Refine by

Energy Applications For The Served Metal Industry In Usa

7 applications found

Energy loss in metal buildings is due primarily from air leakage at the connections (wall/roof, wall/floor, corners, door/window openings and lap seams). Staycell ONE STEP Systems save energy thru a combination of superior air sealing qualities and high R-value, making ONE STEP an attractive alternative to traditional vinyl-faced fiberglass systems. ONE STEP is the optimal solution for new construction and retrofit applications where compliance with new energy codes make the installation of traditional fiberglass ...

ByPreferred Solutions, Inc. (PSI) based in Independence, OHIO (USA)

For 60 years Shamokin has supplied quality carbon and graphite products for numerous hot metals and industrial applications. Shamokin’s major focus is on the Hot Metals Industry. From Shamokin’s inception Steel Mills, and Foundry Products seemed most logical because they are located directly in the center of the Anthracite Coal Region. Anthracite provides the cleanest and lowest sulfur injection carbon for steel ...

ByShamokin Carbons based in Coal Township, PENNSYLVANIA (USA)

Product consistency and purity are essential in the processing of precious metal catalyst. Puragen Activated Carbons offers high purity acid washed products that are manufactured under stringent quality assurance systems and tested in small lots to ensure consistency. ...

ByPuragen Activated Carbons based in Palm Beach Gardens, FLORIDA (USA)

We cooperate with leading world manufacturers of turbochargers, combustion turbines, aviation components and insulation materials based on glass ...

ByPBS Velká Bíteš, a.s. based in Velká Bíteš, CZECH REPUBLIC

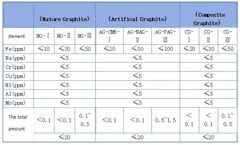

1. Background and Introduction Graphite is crucial for lithium - ion battery (LIB) anode, affecting energy density, cycling stability, and safety. But trace impurities like Fe, Ni, Cu, and magnetic particles can seriously degrade battery performance, leading to side reactions, electrolyte breakdown, and internal short - circuits. As the new energy sector grows, high - purity graphite demand in LIBs surges. Both natural and synthetic graphite need tight quality control (e.g., <1 ppm for critical metals). ...

ByEfficiency Scientific Instrument Co., Ltd (ESI) based in SuZhou City, CHINA

Lubricating oil contains three main types of metal-related elements: additives, wear metals, and contaminants. Additives improve properties like viscosity and anti-wear performance. Monitoring their levels ensures the oil is suitable for the engine. Increased levels of wear metals like iron and copper may indicate abnormal engine wear. Contaminants such as dust and water can degrade oil performance and accelerate component wear. Monitoring these elements helps determine if the oil needs replacement or filtration. ...

ByEfficiency Scientific Instrument Co., Ltd (ESI) based in SuZhou City, CHINA

Removal of debris from metal working processes, also called chips, is one of the most neglected applications of compressed air. Learn how you can save money using nozzles and how you can monitor your savings with the ...

ByVPInstruments based in Delft, NETHERLANDS