Charcoal Powder Articles & Analysis

25 articles found

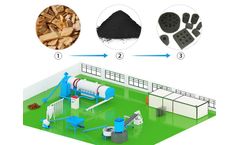

The combustible gases produced during the carbonization process are collected and re-entered the heating system, achieving energy recovery. Charcoal Forming and Processing After carbonization, charcoal powder can be pressed and shaped to improve combustion uniformity. Using a charcoal briquetting machine, the ...

There are several types of briquette machines, each suited to different materials and applications: Types of Briquette Machines Hydraulic Briquette Machine Uses hydraulic pressure to compress materials into briquettes. Suitable for materials like charcoal, metal powders, and mineral powders. Offers high compression and is ideal for producing ...

However, it can be converted into charcoal. There are two ways to do it. One way is always to pack the husk in briquettes and carbonize it to transform it into charcoal. One other method is to first convert rice husk into powdered charcoal after which pack it in briquettes. In case you are doing the work at small-scale, you are ...

Beston charcoal manufacturing plant for sale If you're looking to earn money with the creation of charcoal, you might be thinking about buying a Beston charcoal manufacturing plant. ...

It is really an eco friendly, inexpensive, and productive process. Charcoal making machines use biomass waste as raw material. This equipment is built to reduce the volume of raw material and carbon emissions, as well as to convert it into charcoal powder. ...

This charcoal plant was installed in Russia last year to make sawdust charcoal. The Russian customer then uses the charcoal powder to make fast-burning charcoal briquettes. This continuous charcoal machine can realize the large-scale production of charcoal, and its processing ...

The charcoal-making machine employs powder to make briquettes in varying styles and sizes. ...

The Raymond mill is very common and efficient in the shisha or hookah charcoal and bbq charcoal production line, which can crush and grind the charcoal blocks into fine powder, and then the charcoal powder can be mixed with the binder for making good charcoal briquettes. The ...

You need to take every one of these into mind once you estimate the expense of establishing your charcoal powder making machine.The quickest method to get a rough cost estimate of your biomass pyrolysis plant pricing is to carry out a search within AliBaba.com. ...

The industrial honeycomb coal briquette production line is a series of equipment for deep processing coal powder and charcoal powder, mainly crushers, mixers, coal briquettes forming machines, and dryers. Through this briquettes charcoal processing plant, we can make coal powder and charcoal ...

The industrial honeycomb coal briquette production line is a series of equipment for deep processing coal powder and charcoal powder, mainly crushers, mixers, coal briquettes forming machines, and dryers. Through this briquettes charcoal processing plant, we can make coal powder and charcoal ...

Industrial charcoal processing equipment is essential for the modernization of charcoal production. ...

Charcoal manufacturing plant typically describes converting biomass into charcoal through the entire process of pyrolyzing under oxygen-free atmosphere and extreme temperatures. ...

A charcoal making machine is a valuable item of equipment to have when you need to transform waste into charcoal powder. ...

How To Improve Efficiency Of Charcoal Briquette Production Line 1. The core of the charcoal briquette production line is the formation of pressure, so choose a high-quality briquette press machine is very important. ...

The charcoal briquette production line equipment utilizes the principle of gasification carbonization and adopts advanced smoke-free environmental carbonization. ...

You may pick them up on a daily basis, drive them straight back to your organization, and commence turning them into charcoal. The Beston Charcoal Making machine uses gas to transform the coconut shells into charcoal. ...

A biomass pyrolysis plant is some industrial charcoal making equipment utilized to convert various biomass waste into biochar. ...

Requirements For Converting Coconut Shells Into BioChar • The moisture content of raw materials has to be under 50% to ensure charcoal output with a high carbon percentage. Note: Charcoal with a carbon percentage exceeding 95% is much more profitable mainly because it has higher thermal value and produces less smoke when burnt. ...

Charcoal powder briquette machine is a series of charcoal briquette machine equipment with the technical content of equipment. ...