Coal By Oil Agglomeration Process Articles & Analysis: Older

19 articles found

Coal washing is a process through the impact of water flow, raw coal with different components and specific gravity is separated into different grades. It can remove dust and waste rock and reduce the ash and sulfur content. Coal washing is an indispensable link in coal processing. The coal after coal washing is called clean coal. Coal washing can achieve the purpose of environmental protection, ...

HDPE Pond Sheet Liner for Coal Chemical Industry in Indonesia Coal chemical industry refers to the conversion of coal into gas, liquid and solid through chemical processing using coal as raw material, Bulk fuel and chemical processes. It mainly includes coal gasification, liquefaction, carbonization and coke, petroleum processing and calcium carbide acetylene chemical industry. With the ...

Application Area: Iron & Steel Industry Process: Coal Injection Measuring Components: O2, COApplication Scenario: Pulverized Coal Injection is the key to optimizing the blast furnace process for high productivity as well as hot metal cost. In this process, the raw coal is fed into the pulverizer along with heated air. As the coal gets crushed, the hot air dries it and blows the usable fine ...

The industrial honeycomb coal briquette production line is a series of equipment for deep processing coal powder and charcoal powder, mainly crushers, mixers, coal briquettes forming machines, and dryers. Through this briquettes charcoal processing plant, we can make coal powder and charcoal powder into solid briquettes of different shapes. And these coal or charcoal briquettes can be used for ...

The industrial honeycomb coal briquette production line is a series of equipment for deep processing coal powder and charcoal powder, mainly crushers, mixers, coal briquettes forming machines, and dryers. Through this briquettes charcoal processing plant, we can make coal powder and charcoal powder into solid briquettes of different shapes. And these coal or charcoal briquettes can be used for ...

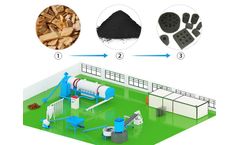

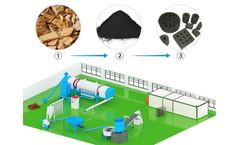

Industrial charcoal processing equipment is essential for the modernization of charcoal production. Different specifications of charcoal production lines and charcoal processing solutions have improved production efficiency for thousands of charcoal processors and created considerable benefits. The charcoal production line is a general term for a series of charcoal and coal processing equipment. ...

Building a biomass charcoal briquette plant will help to reduce other fuel costs and make extra value from the biofuel briquette. Charcoal briquette machine is the indispensable equipment in the charcoal briquette production line. Why Make The Charcoal Briquette Plant For Biomass Waste Among the world’s major energy components, biomass energy is now one of the most rapidly growing energy ...

Abstract The present paper describes the steps followed to develop a detailed and reliable combustion modelling procedure whose application as major engineering design tool supported AC-Boilers (ACB), a major Italian boiler manufacturer, in routing its products development to highly efficient burners for power generation purposes, while adopting a significantly reduced time to market. In 2018, in ...

Burning of coal nowadays has become a big problem. The main reason for this is a rapid increase of mankind. So, China burns half of coal in the world. Since 2000 the share of coal in world energy production has increased from 25 to 30%, and the Chinese economy is responsible for 82% of this growth. In Beijing, it is customary to use individual heat sources such as electric heaters and the like. ...

Our subsidiary SWR Engineering has launched the M-Sens 2 sensor for the continuous measurement of humidity on solids of all kinds. It can ideally be used, for example in container outlets, conveyor belts, conveyor screws, mixers and conveyor dryers... Application An operator of a coal fired power plant uses brown coal for the firing and therefore the production of energy. In an other part of ...

ByENVEA

We developed a new calcination method to convert coal gangue (CG), a common waste generated from coal production process, into a modified form, which could be used as an adsorbent to remove Mn2+ from aqueous solution. Sodium tetraborate (Na2B4O7·10H2O) was added into the CG calcination process as an additive, and the concentrations of Na2B4O7·10H2O were optimized along with the calcination ...

It’s time to move towards non-renewable to renewable sources to protect earth and environment from pollution and global warming. As we know there are many renewable Energy sources are available on the earth. For ex. Sun, wind, water, Biomass etc. all renewable energy sources produce energy which never affect to our climate. Let’s we discuss about one of the Renewable Energy ...

In this study, oil agglomeration process has been employed to clean indigenous coal under the influence of parameters such as oil type, particle size and the pH value of aqueous medium. ...

Tea manufacturing industries in India use natural gas, tea drying oil, wood, and coal for process heat. India is the second largest producer of tea [(1,137.07, China 1,761.00) million kilogram] in 2012. About 0.6–1.2 kg of coal is required to produce one kilogram of dried tea with average moisture of 2.5–3 percentage (w.b.). Biomass gasification is an established renewable energy technology for ...

What is “coal-water fuel”? Coal-water fuel (CWSF or CWS or CWF) is a fuel which consists of fine dispersed coal particles, water and plasticizing agent. This type of fuel is widely used as an alternative to gas and black oil on different heat generating facilities. The operational economy is the main of advantages of the coal-water fuel. CW fuel has almost the same heat ...

Clarke Energy has signed a deal with Australia Pacific LNG to provide a 30MW temporary power plant to their coal seam gas processing plant in Queensland. Clarke Energy to provide 30 MW temporary power station to support operation of Reedy Creek coal seam gas processing facilities Australia Pacific LNG, a joint venture between Origin Energy, ConocoPhillips and Sinopec, is developing an integrated ...

Addressing the environmental risks related to contamination of groundwater with the phenolics, benzene, toluene, ethyl benzene, xylene (BTEX) and polycyclic aromatic hydrocarbons (PAHs), which might be potentially released from the underground coal gasification (UCG) under adverse hydrogeological and/or operational conditions, is crucial in terms of wider implementation of the process. The aim ...

TenCate helps North River Mine continue processing coal by utilizing first ever large-scale Geobag disposal method. In 2007, the North River Mine coal processing plant in Berry, Alabama was in a bind. Due to new regulatory restrictions, available area, and construction scheduling, the plant was facing a possible interruption of the primary disposal methods of its refuse - a waste stream of ...

The problem of producing synthetic liquid fuels by alternative routes is addressed. Industrial processes known as Gas To Liquid (GTL), Coal To Liquid (CTL) and Biomass To Liquid (BTL) are considered: they use natural gas, coal and biomass as feedstocks, respectively. By means of process simulation, it is shown that the fuel produced on a weight basis per unit of feedstock (natural gas, coal and ...