Refine by

Heat Recovery System Articles & Analysis

56 articles found

The mill has inaugurated its combined heat and power (CHP) system which is comprised of a Taurus™ 70 gas turbine generator set, an air system with fans, burners, dampers, ducting and instrumentation for the hood, as well as a heat recovery steam generator, an air/ air heat ...

In 1987, the University invested in a 4.5 MW natural gas turbine CHP system with a heat recovery steam generator (HRSG) capable of providing 56,000 Ibs/hr steam for use in the University's central heating system. ...

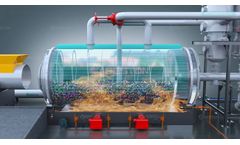

Moreover, the integration of indirect heating systems—where heat is transferred through reactor walls rather than direct flame contact—minimizes hot spots and material degradation. This method also prolongs the lifespan of internal components and refractory lining. Enhanced Insulation and Heat ...

DOING charcoal carbonization plant can achieve continuous feeding, effectively improve production efficiency, reduce manpower requirements, and more stable product quality through automation, stabilization and efficiency. 3. Carbonization Process Heating: The heat source heats the reactor, and the raw materials undergo pyrolysis in the ...

The equipment is equipped with an advanced automatic control system, which can realize accurate monitoring and regulation of the entire carbonization process. ...

The Town of Caledon, self-proclaimed “Greenest Town in Ontario,” demonstrates its commitment to sustainability through successful energy management initiatives that have reduced consumption and costs while preserving its heritage and fostering community progress ...

Equipped with advanced features such as heat recovery systems and automated controls, these machines optimize the conversion process, minimizing energy consumption and emissions. ...

The efficiency with which the reactor manages and utilizes heat can significantly impact the yield and quality of these byproducts, making it an essential consideration in the design and operation of pyrolysis systems. ...

The pyrolyzed oil vapor is condensed into liquid form, while the remaining gas is either collected or recycled to fuel the reactor, and carbon black is separated for further processing. Effective recovery systems reduce cycle time by quickly and efficiently sorting products without interrupting the pyrolysis flow.Discharge of Solid Residues: Continuous plants are ...

Opt for a machine that incorporates heat recovery systems and minimizes energy waste. Investing in an energy-efficient carbonizer not only lowers operating costs but also enhances the sustainability of your production line, making it a more attractive option for investors and regulators alike. ...

Cooling System: Once carbonized, the charcoal requires cooling to stabilize its structure and prevent spontaneous combustion. ...

This thermochemical transformation subjects coconut shells to high temperatures in the absence of oxygen, leading to the breakdown of complex organic compounds and the production of high-quality charcoal. Mechanisms for Efficient Heat Recovery and Utilization Efficiency is paramount in the operation of these machines. Advanced heat ...

The equipment utilizes various heating mechanisms, such as direct combustion, hot gases, or electric heating elements, to reach and maintain the required temperatures. ...

Assessing Energy Efficiency and Environmental Sustainability Energy efficiency and environmental sustainability are crucial aspects of a well-designed pyrolysis plant. Evaluating the efficiency of heat transfer mechanisms, such as the use of advanced insulation materials and heat recovery systems, can significantly impact the ...

As a result, of continuous hours of operators, the original Kemco equipment was nearing the end of its service life, leading UTD to investigate replacing system components and adding new equipment.Solution The goal was to replace and upgrade the controls to bring the heat recovery system back online as well as incorporate a steam ...

Organic Rankine Cycle working principle The Organic Rankine Cycle has characteristics that make it ideal for heat recovery and the exploitation of low-temperature heat sources in general. ...

While this is not a new technology, traditional heat recovery systems were restricted to industries with high temperature heat such is found at large power plants – making widespread adaptation virtually impossible. ...

As indicated above, while a turbine system may be ideal for higher temperature heat sources with a consistent flow, they tend to be unsuitable for many waste heat recovery opportunities that screw expander systems are able to capitalize on due to their superior transient operation capabilities. ...

Plant: 1 x ZE-50-LT Low-Temperature Organic Rankine Cycle (ORC) Module, nominal output 50 kWe Nominal output: 50 kWe Application: Heat recovery from engines (two MAN biogas-fueled gensets) Location: Province of Padua, Veneto, Italy Manager: Private Italian firm The cattle farm which commissioned this plant lies in a small village in a corner of the province ...

The mill has inaugurated its cogeneration system which is comprised of a Taurus™ 70 gas turbine generator set, an air system with fans, burners, dampers, ducting and instrumentation for the hood, as well as a heat recovery steam generator, an air/air heat recovery and an air/water ...