Heat Recovery Technologies Articles & Analysis

56 articles found

The Lucart Castelnuovo di Garfagnana tissue mill is part of the Lucart Group, one of the first European paper and tissue producers. The mill has inaugurated its combined heat and power (CHP) system which is comprised of a Taurus™ 70 gas turbine generator set, an air system with fans, burners, dampers, ducting and instrumentation for the hood, as well as a heat recovery steam generator, an ...

Eastern Michigan University (EMU) is located in Ypsilanti, Michigan, approximately 35 miles west of Detroit and 8 miles east of Ann Arbor. It was founded in 1849 as a small teachers college and today has grown into a major public learning and research institution with over 21,000 students. EMU historically has been a leader in energy efficiency and sustainability. In 1987, the University ...

As global emphasis on energy efficiency intensifies, advancements in pyrolysis technology have shifted toward optimizing heat utilization and minimizing energy loss. ...

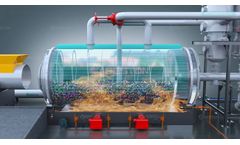

DOING charcoal carbonization plant can achieve continuous feeding, effectively improve production efficiency, reduce manpower requirements, and more stable product quality through automation, stabilization and efficiency. 3. Carbonization Process Heating: The heat source heats the reactor, and the raw materials undergo pyrolysis in the ...

These equipments use advanced pyrolysis technology to pyrolyze various biomass raw materials, such as wood waste, agricultural straw, fruit shells, etc., in an oxygen-free or low-oxygen environment, and convert them into high-quality biomass charcoal, biomass gas and biomass oil. ...

The Town of Caledon, self-proclaimed “Greenest Town in Ontario,” demonstrates its commitment to sustainability through successful energy management initiatives that have reduced consumption and costs while preserving its heritage and fostering community progress ...

Equipped with advanced features such as heat recovery systems and automated controls, these machines optimize the conversion process, minimizing energy consumption and emissions. ...

Well-insulated reactors and advanced heat recovery systems help minimize energy waste. By efficiently recycling heat within the system, the reactor can operate with reduced external energy input, leading to significant cost savings in the long run. ...

A continuous pyrolysis plant is designed to streamline the conversion of waste materials, such as plastics and tires, into valuable resources like fuel oil, carbon black, and syngas. Understanding its operating cycle time is essential for businesses and operators to achieve efficiency, maximize output, and make informed decisions about processing volumes, energy usage, and maintenance scheduling. ...

Opt for a machine that incorporates heat recovery systems and minimizes energy waste. Investing in an energy-efficient carbonizer not only lowers operating costs but also enhances the sustainability of your production line, making it a more attractive option for investors and regulators alike. ...

Finally, they are packaged for distribution and sale. Advanced Technologies and Innovations Advancements in technology have revolutionized hookah charcoal production, introducing efficiency and sustainability of charcoal briquette machine: Continuous Carbonization Systems: These systems allow for uninterrupted processing, minimizing downtime and maximizing ...

This thermochemical transformation subjects coconut shells to high temperatures in the absence of oxygen, leading to the breakdown of complex organic compounds and the production of high-quality charcoal. Mechanisms for Efficient Heat Recovery and Utilization Efficiency is paramount in the operation of these machines. Advanced heat ...

In the realm of sustainable technologies, pyrolysis equipment stands out as a versatile and efficient solution for thermal conversion. ...

In the realm of waste management, pyrolysis plant has emerged as a groundbreaking solution to tackle environmental challenges while harnessing the potential of waste. With a wide range of options available in the market, choosing the right pyrolysis plant for sale can be a daunting task. This article aims to guide prospective buyers in their decision-making process, ensuring they make an informed ...

Executive Summary Up To Date Laundry (UTD) is one of the largest healthcare laundry providers on the east coast and the state of Maryland’s largest commercial laundry facility. Approaching 70 years of operations, UTD processes approximately 50 million pounds of linen at its Baltimore facility.Problem Up To Date Laundry facility operates 24/7 which allows little to no downtime to maintain or ...

Organic Rankine Cycle working principle The Organic Rankine Cycle has characteristics that make it ideal for heat recovery and the exploitation of low-temperature heat sources in general. ...

However, thanks to recent advancements in ORC technology, heat sources as low as 70°C can now benefit from waste heat recovery. ...

ORC power generation is a sustainable technology that reduces the amount of energy consumed (fuel) and energy wasted (heat). ...

Plant: 1 x ZE-50-LT Low-Temperature Organic Rankine Cycle (ORC) Module, nominal output 50 kWe Nominal output: 50 kWe Application: Heat recovery from engines (two MAN biogas-fueled gensets) Location: Province of Padua, Veneto, Italy Manager: Private Italian firm The cattle farm which commissioned this plant lies in a small village in a corner of the province of Padua adjoining the province of ...

OWNER Lucart Group LOCATION Province of Lucca, Italy DIRECT DRYING DESIGN AND SUPPLY Valmet PRODUCT Taurus 70 Gas Turbine CUSTOMER VALUE Efficient and Sustainable Power The Lucart Castelnuovo di Garfagnana tissue mill is part of the Lucart Group, one of the first European paper and tissue producers. The mill has inaugurated its cogeneration system which is comprised of a Taurus™ 70 gas ...