Heat Recovery Unit Articles & Analysis

11 articles found

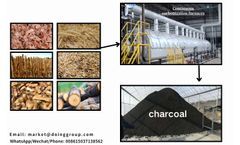

Biochar is a solid product formed by heating biomass in the absence of oxygen through pyrolysis technology. ...

Advanced Thermal Management and Heat Recovery Modern reactor systems are engineered with multi-zone temperature control, allowing operators to fine-tune the thermal environment at different stages of the process. This zoned heating ensures that volatile components are efficiently cracked without over-carbonizing the residue. Integration with ...

That’s fine, what they have in common is a device called a heat exchanger. Now believe it or not, you are probably quite familiar with one heat exchanger, but know it under a different name; it’s the radiator in your car. Heat exchangers are critical for keeping various devices cool so that they don’t overheat and malfunction. ...

A simple, self-controlling and cost effective heat recovery system was required in order to satisfy the following conditions required by the plant: Harness the maximum amount of waste heat from the drying process based on varying waste heat source and heat demand The dryer gas pressure balance must be ...

De-commissioning an old inefficient recuperative oxidiser which was attached to a single process stream and contained a low thermal effectiveness thermal efficiency heat recovery unit Redirecting & relocating ductwork to take the process stream away from the old oxidiser and introduce it into the existing RTO Add individual bypass stacks to ...

“A number of years ago Sid Abma of Sidel Systems USA Inc. approached us with his Sidel SRU flue gas heat recovery unit. I think that we, like most companies, considered it; but we took no action for some time. Finally a situation developed that made it beneficial for us to try this unit. We purchased a unit ...

OVERVIEW A coil coating facility purchased a new a 15,000 SCFM Regenerative Thermal Oxidizer (RTO) which had a nominal heat transfer efficiency rate of 90% thermal energy recovery. It was designed with supplemental fuel injection (SFI) which is used during low VOC loading conditions, to help save fuel cost. ...

It can be achieved by the exploitation of waste heat for water production and climate control with new technologies such as membrane distillation and water recovery from desiccant solutions. Humidity control in air treatment is regularly connected to condensation processes using heat pumps. The use of liquid desiccants for air de-humidification ...

CPS were contracted to design and manufacture six thermoplastic heat exchangers complete with spray cleaning systems as part of the building’s heat recovery system. The units are designed for extraction flow rates of 17,172 m3/hr and 20,196 m3/hr, manufactured from polyethylene with polypropylene housings. The ...

Employees Highly experienced: our employees average 14 years of nitrogen pumping services Equipment Incorporates the latest technology available Meets high standards of quality, maintained in-house Offers both heat recovery and burner units Management Committed to providing the best training possible Dedicated to the highest safety ...

Boiler/Cogen Heat/Energy Recovery Application Thermal Energy installed designed and implemented an integrated FLU-ACE heat recovery system with cogeneration unit for efficient electrical power generation and an overall reduction in energy consumption. The installation consists of a natural gas fueled engine ...