Producing Syngas Articles & Analysis

32 articles found

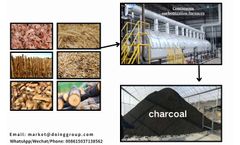

Significant Environmental Benefits: The carbonization process using a charcoal maker machine is cleaner than direct incineration, minimizing smoke emissions and meeting modern environmental standards. Furthermore, charcoal produced through a charcoal making machine produces significantly less smoke and harmful gases when burned than traditional charcoal. Whether ...

To help customers carbonize and produce more efficiently, DOING provides crushers and dryers to pretreat biomass raw materials. ...

A new dawn for carbon utilisation in petrochemicals Imagine a world where the very emissions once considered a burden have become the foundation for cleaner, more efficient fuels. The petrochemical industry is on the brink of achieving such a transformation. The landscape is shifting away from decades-old traditional processes that, while profitable, have contributed significantly to global ...

BySpecac

At lower temperatures, the yield of charcoal is higher, but the quality may suffer in terms of heat output and burn time. Higher temperatures produce more refined charcoal, but at the cost of reduced yield. A balanced approach is essential. ...

Like gasification, it involves heating biomass to high temperatures, but the goal is different. Instead of producing a gaseous mixture like syngas, pyrolysis converts biomass into solid, liquid, and gas products in varying proportions, depending on the operating conditions. ...

Lignin pyrolysis occurs at higher temperatures (around 350-500°C) and produces a significant amount of bio-oil and syngas, with less biochar. ...

Carbonization Process The heart of the charcoal making process is carbonization, where raw materials are heated in an oxygen-free environment to produce charcoal. The video showcases how this process works, including how heat is applied and maintained within the reactor. You will also see how syngas, a by-product, is captured and used to fuel the system, making ...

The use of syngas for power generation is particularly advantageous because it produces fewer emissions than coal or natural gas. ...

Gas and Liquid Separation: The vaporized gases and liquids produced during pyrolysis are routed to a separation system, where they undergo cooling and condensation to convert them into marketable products such as syngas, pyrolysis oil, and carbon black. ...

Pyrolysis, the thermochemical decomposition of organic materials in the absence of oxygen, has emerged as a potentially lucrative technology for waste management and resource recovery. However, embarking on a pyrolysis venture necessitates a thorough understanding of the economic viability of the process. This article delves into the intricacies of pyrolysis profit analysis, equipping potential ...

These machines are capable of processing a wide range of feedstocks, including biomass, plastics, rubber, and organic waste, to produce useful outputs such as biochar, bio-oil, and syngas. Operational Principles The operational principles of small pyrolysis machine revolves around controlled heating and thermal decomposition of feedstock materials. ...

However, the challenge lies in refining the bio-oil to meet stringent quality standards, a task that demands precision in the operational corridors of the plant.Syngas: Gaseous Energy AlchemyThe gaseous offspring, syngas, is a concoction of carbon monoxide, hydrogen, and methane. This versatile energy carrier can be harnessed for electricity generation or as a precursor for the ...

The global pursuit of sustainable and renewable energy sources has led to innovative technologies that harness the potential of biomass. In the heart of this green revolution lies palm kernel shell pyrolysis, a process that transforms palm waste into valuable green fuel. This article delves into the intricacies of palm kernel shell pyrolysis, exploring the technology, environmental impact, ...

The transition to sustainable energy is a critical global goal, and biogas and syngas are emerging as significant contributors to this shift. Cambridge Sensotec’s advanced gas analysis technologies are playing a pivotal role in ensuring the efficient and effective use of these renewable energy ...

Biochar is a carbon-rich material produced by heating organic matter, such as agricultural and forestry waste, in a low-oxygen environment—a process known as pyrolysis. ...

Generating Sustainable Energy and Biochar Charcoal making machines are not just waste converters; they are energy generators. The process produces syngas – a combustible mixture of hydrogen, carbon monoxide, and other elements – that can be harnessed for electricity and heat generation. ...

Unleash the power of Syngas Analysis in Biomass Gasification Applications. The aim of this blog is to decode this subject. Delve deep into the process, its impact, and its benefits. An enlightening journey ...

Additionally, continuous pyrolysis plants generate revenue through the sale of by-products such as pyrolysis oil, carbon black, and syngas. These products have various industrial applications and can create additional income streams for the plant owners. ...

For example, using lower temperatures and longer residence times can lead to a greater yield of bio-oil, while higher temperatures and shorter residence times will favor producing syngas. Some great benefits of pyrolysis Pyrolysis offers numerous potential benefits over other ways of waste management. ...

Syngas production from waste gasification is one way to produce renewable energy. ...