Refine by

Pyrolysis Plant Articles & Analysis: Older

482 articles found

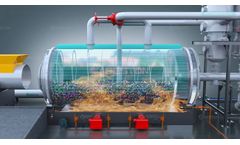

This process is commonly used for smaller-scale pyrolysis plants or where the input materials vary in size and type. While batch pyrolysis offers flexibility, it can be less efficient compared to continuous pyrolysis because of the downtime between batches. 2. ...

Control System and Electrical Equipment A reliable and automated control system is essential for managing the continuous operation of the pyrolysis plant. PLC Control System: A Programmable Logic Controller (PLC) is used to monitor and control all aspects of the pyrolysis process, including the feeding system, reactor temperature, gas collection, ...

The thermal efficiency of a pyrolysis reactor is a critical factor in determining the overall performance, energy consumption, and economic feasibility of the pyrolysis process. ...

The operating cycle time in a continuous pyrolysis plant is the complete duration required for raw waste materials to enter, undergo pyrolysis, and exit as refined end products. Unlike batch or semi-continuous pyrolysis plants, where processing takes place in phases, continuous pyrolysis operates ...

The relative proportions of these components influence the yields and characteristics of the pyrolysis products. 2. Pyrolysis Process: During pyrolysis, biomass is heated in the absence of oxygen, causing it to break down into smaller molecules. The biomass fraction that converts into gaseous and liquid products varies depending on factors like ...

Sealing is a crucial factor in the overall performance and efficiency of a pyrolysis reactor. The technology behind pyrolysis revolves around the thermal decomposition of materials in the absence of oxygen. ...

Choosing the right supplier for your pyrolysis plant is essential for ensuring high efficiency, reliable performance, and long-term success. Among the various suppliers in the market, Beston Group stands out as a leader in the pyrolysis industry. Let's explore why Beston Group should be your preferred choice for pyrolysis ...

Large-scale pyrolysis plants are often more suitable for higher volume operations, so starting with a smaller unit might be more cost-effective and practical. ...

The mini pyrolysis plant represents a significant opportunity for investors looking to enter the waste-to-energy sector. ...

Job Creation: The establishment and operation of plastic pyrolysis plants can create jobs and stimulate local economies. This includes roles in plant operation, maintenance, and management. Practical Benefits Scalability: Plastic pyrolysis systems can be scaled to meet varying levels of demand. This flexibility allows for ...

In January 2014 BTG Bioliquids / Empyro BV started construction of its pyrolysis oil production facility in Hengelo, the Netherlands. The Empyro plant converts 5 tons per hour of wood residues into pyrolysis oil, process steam and electricity. ...

The Swedish joint venture Pyrocell, consisting of the wood industry company Setra and the oil company Preem, will be utilising BTG Bioliquids technology. Construction of the pyrolysis facility has started in 2020 and production in September ...

GFN Lieksa is a Green Fuel Nordic subsidiary operating a BTG Bioliquids fast pyrolysis bio-oil plant in the Kevätniemi industrial area in Lieksa. ...

This article outlines the types of raw materials suitable for pyrolysis and describes the general process flow of a waste pyrolysis machine. 1. ...

Let's delve into why this could be your first choice investment. What is a Mobile Pyrolysis Plant? A mobile pyrolysis plant is a cutting-edge piece of equipment that converts organic waste, such as agricultural residues, wood waste, and even plastic, into valuable products like bio-oil, biochar, and syngas. ...

Reduce pipe blockage:Beston cataytic plastic pyrolysis plant solves the wax oil blocking piples problem, reducing downtime. ...

This article delves into the intricacies of pyrolysis profit analysis, equipping potential investors with the knowledge to make informed decisions.Factors Influencing Profitability A multitude of factors influence the profitability of a pyrolysis operation. ...

Prolonged exposure to these chemicals through inhalation or ingestion increases the risk of developing various forms of cancer, including lung cancer, bladder cancer, and soft tissue sarcoma. Emerging Technologies 1. Pyrolysis Pyrolysis is an innovative thermal treatment process that breaks down plastic waste into syngas, oils, and char through high-temperature ...

The concept of a mobile pyrolysis unit stems from the need for flexibility in waste processing. Traditional pyrolysis plants are often stationary, limiting their reach and efficiency. ...

The evolution from batch to continuous pyrolysis plants marks a transformative leap in waste management technology, redefining efficiency and sustainability standards. The superiority of the continuous pyrolysis plant over its batch counterpart is manifest in its seamless, uninterrupted operation. ...