Abwood Machine Tools products

Photovoltaics

Model TS 3 - Twin Spindle Surface Grinders for Multi-Crystalline Silicon

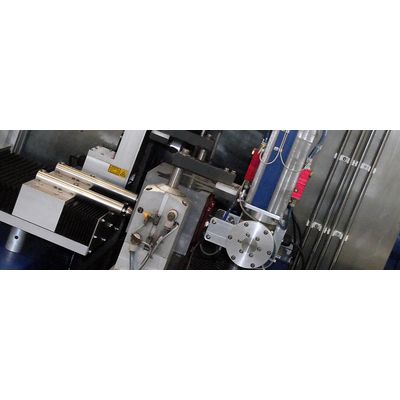

The TS3 continues the development of twin spindle surface grinders for multi-crystalline silicon. The new design addresses the need for side face and chamfer grinding in one machine whilst increasing capacity up to a maximum block length of 400mm. The machine is designed to operate within an automated production environment and includes a handling interface for component exchange with a factory automation system. With this requirement in mind, the machine is self adjusting and is capable of running in a 24hr production environment with minimal operator intervention.

Model TS 3Q - Twin Spindle Surface Grinders for Multi-Crystalline Silicon

The TS3Q continues the development of twin spindle surface grinders for multi-crystalline silicon from Abwood Machine Tools. The new design addresses the superior surface finish by combining rough and fine grinding in one process whilst also increasing capacity up to a maximum block length of 400mm. The TS3Q retains the ability to operate within an automated production environment and includes a handling interface for component exchange with a factory automation system.

Abwood - Model TS 5 - Grinding Process for Mono-Crystalline Silicon Ingots

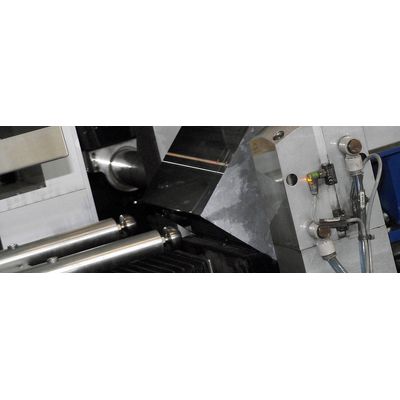

The Abwood TS5 has revolutionised the grinding process for mono-crystalline silicon ingots. Following on from the existing range of twin spindle surface grinders for multi-crystalline silicon, the new design offers the capability of flat face grinding and radius or flat corner grinding in one process. The machine is capable of handling ingot sizes 125mm square, 156mm square and 210mm square and is self adjusting for lengths from 150mm up to 1020mm.

Model CM 74 - Grinding Standard Chamfered Edges On Multi-Crystalline Silicon Ingots

Capable of grinding standard chamfered edges on multi-crystalline silicon ingots, the CM74 is aimed at high volume manufacture and is a perfect complement for the TS2 Surface Grinding machine in a cellular manufacturing environment. The machine addresses the need for superior surface finish on chamfers by utilising multiple spindles to grind all four chamfers simultaneously thus allowing for a substantially slower linear in feed rate. The CM74 retains the ability to operate within an automated production environment and includes a handling interface for component exchange with a factory automation system.

Model CM 12H - High Power Single Spindle to Remove Material for Photovoltaics

The Abwood CM12H utilises a high power single spindle to remove material from the bottom or top of sawn multi-crystalline blocks. This maybe used as an alternative to saw cropping of block ends where the material to be removed is minimal.

Surface Grinding

Model RG 1 - Rotary Tabled Surface Grinding Machine

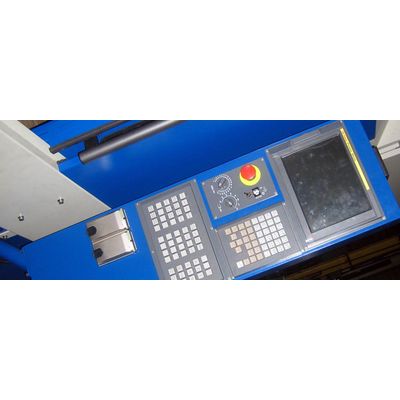

The RG1CNC is the final evolution of the proven rotary tabled surface grinding machine range from Abwood Machine Tools. Featuring a full CNC control with customised grinding canned cycles it is possible to achieve highest component accuracy with minimal operator knowledge. Available in table diameters up to 600mm and capable of using grinding wheels up to 400mm diameter the RG1 series of surface grinders offers maximum capacity whilst maintaining a relatively small footprint.

Model RG 2 - Rotary Tabled Surface Grinding Machine

The RG2 is the latest design in the range of rotary tabled surface grinding machine range from Abwood Machine Tools. Featuring a full CNC control with customised grinding canned cycles it is possible to achieve highest component accuracy with minimal operator knowledge. Available in table diameters from 800mm to 1200mm and capable of using grinding wheels up to 500mm diameter the RG2 surface grinder offers an extremely high capacity in spite of the small footprint.