NESS Warmetechnik GmbH products

Thermal Oil Heaters

Direct Firing Heaters

The NESS Thermal oil heater - the core component of your heating supply system.

Generators

Integrated Process Heat Generation

When integrated into the production process NESS systems supply your installations with all variations of temperature. Well devised concepts lead to an economic usage of heat, for example:

Steam, Hot and Warm Water Generators

We plan and implement our steam systems using pressure vessels either made by us or from renowned west-European manufacturers. In our hot-water systems we use either fire-tube smoke heaters from renowned manufacturers or our own coiled-pipe principle (depending on the industrial requirements). We also install many other approved components from our own production in our systems. At the same time we place our many years of experience from planning application-oriented, ready-to-use, complete systems at your disposal.

Process Heat

NESS - Thermal Oil Systems

For heating at a high temperature level. Thermal oil plants are used in almost all manufacturing industries. The decision for a thermal oil plant is almost obvious for some processes, as thermal oil has many compelling properties. For example, the operation of the plant is possible up to a temperature of about 350 ° C almost without pressure and extremely efficient. As an expert in process heat, we are the right partner for all questions regarding the temperature control of your process plants. All NESS products are thermodynamically optimized. We attach great importance to high efficiency, longevity, safety and availability as well as excellent heat transfer of our systems. Our development team is happy to develop new solutions with you. Your success is important to us, so that together we can design and optimize your plant individually for you.

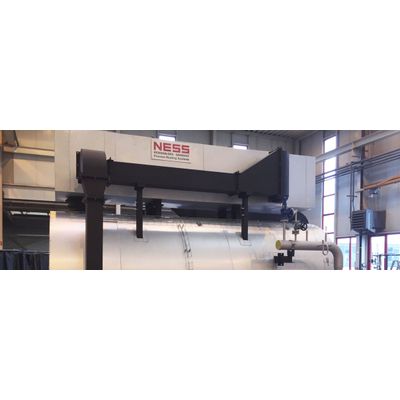

NESS - Fired Thermal Oil Heaters

Fired heaters for gaseous and liquid fuels. Experience the difference with NESS oil heaters by achieving high efficiency, excellent heat transfer and low film temperatures. Our goal is achieving the highest efficiency which not only saves on fuel costs but also reduces CO2 emissions making operations more sustainable. NESS thermal oil heaters offer a special design that yields a balanced temperature profile. Doing so actively prevents temperature peaks and with the flow optimized within the heater, dead zones are prevented. This virtually eliminates oil overheating within the system. Built-in components are user-friendly and meet all required safety standards. The heaters are available in two different series: horizontal (WEH) and vertical (WEV).

NESS - Electric Thermal Oil Heater

The electrical alternative to fired heaters. The electric thermal oil heater (EWE) is a real alternative to fired heaters and, in addition to continuous operation, it is also suitable for bridging peak loads and during retrofits to the system. EWE has a very small footprint and can be easily integrated into most thermal oil systems. Another big advantage is the purely electrical heating. Since the heater does not include a fi ring system, there are no exhaust fumes that may require a fi ring permit procedure. Since it does not consume fossil fuels, it also eliminates the need for fuel storage as well as the supply and handling costs. In addition, other infrastructure such as chimney and fuel tank is not needed. With our electric heaters, the power can be regulated in multiple stages or alternatively steplessly.

NESS - Biomass Plants

Creating process heat using biogenic solid fuels. Biomass plants use organic solid fuels such as sawdust, wood chips, timber or landscape management by products to produce hot flue gases. Biomass is an excellent alternative to generating heat using conventional fossil fuel products. Depending on their quality, these solid biomass fuels can create high demands on a plant. The combustion process, the heating components and the legal and emission regulations must be considered.

NESS - Heating and Cooling Systems

Heating-cooling circuits for machines and devices. Numerous production processes require heating-/cooling systems. These processes are additionally dependent on a high-precision temperature maintenance, in particular of temperature gradients, such as in a printed circuit board production or plastic production in aircraft industries. As an expert in process heat, we are the right partner for all questions regarding the temperature control of your process plants. All NESS products are thermodynamically optimized. We attach great importance to high efficiency, longevity, safety and availability as well as excellent heat transfer of our systems. Our development team is happy to develop new solutions with you. Your success is important to us, so that together we can design and optimize your plant individually for you.

NESS - Secondary Circuits

Precise process temperature independent of the flow temperature in the network. With the secondary circuit, the heating parameters (temperature, temperature level, volume flows and pressures) can be optimally adapted to the requirements of the process. The temperature can be regulated very precisely and is therefore ideal for demanding processes.

NESS - Heat Recovery System

More efficient use of existing resources. An interesting approach for your heating system is the heat recovery through a combustion air preheater (Luvo). The Luvo makes it possible, for example, to actively use the remaining exhaust gas energy at the outlet of the heater in order to save energy costs and raw materials! With this type of heat recovery, you can not only save fuel accordingly, but also actively reduce the CO2 emissions of your system.