4 products found

Plasma-Therm products

ETCH

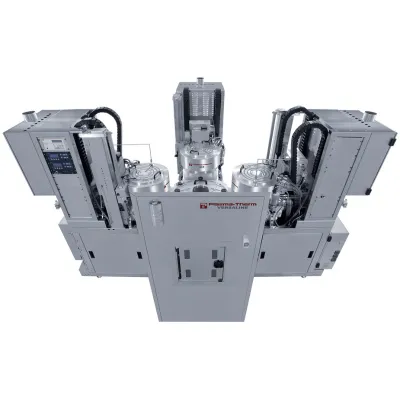

VERSALINE - Semiconductor Processing Systems

The VERSALINE platform from Plasma-Therm is engineered to support a broad spectrum of applications within the specialty semiconductor markets, primarily focusing on etching and deposition processes. With its modular design, VERSALINE allows for flexible substrate handling configurations, making it suitable for both research and development and high-volume production environments. The platform incorporates several advanced technologies, including Ion Beam Etch (IBE), Ion Beam Deposition (IBD), and various types of plasma-enhanced chemical vapor deposition (PECVD). These systems are known for their high uniformity, throughput, and cost-efficiency. The onboard Cortex control system ensures user-friendly operation with features like EndpointWorks for enhanced process control. Versatility is enhanced with options for inductive coupled plasma (ICP), deep silicon etching (DSE), and high-density radical flux (HDRF) technology, catering to diverse semiconductor processing needs from low-damage etching to high-aspect-ratio applications.

Plasma-Therm - Parallel-Plate Reactive Ion Etching Systems

Plasma-Therm's Tegal 900 Series comprises industry-standard parallel-plate reactive ion etching systems designed for descum and noncritical dielectric etching applications. These systems are engineered to deliver high efficiency and reliability, occupying a minimal footprint. They offer flexibility in configuration with both manual and cassette loading options, catering to different manufacturing setups. The systems are part of the Tegal Etch Systems family, renowned for their cassette-to-cassette platforms in volume manufacturing contexts. The Cortex control system enhances user interaction with a stable, efficient interface that boosts productivity. Furthermore, Plasma-Therm extends support for various legacy Tegal products, such as the 901e, 903e, 901g, and 6500 HRe cluster tools, including spare parts and upgrades. This commitment ensures the long-term value and adaptability of their etching solutions.DEPOSITION

Plasma-Therm - PVD System for Semiconductor Processing

The Eclipse Mark IV PVD system, an enhancement over the Mark II, serves as a versatile solution for semiconductor processing. This physical vapor deposition (PVD) system is adept at depositing metals essential for interconnects, via fill, silicides, and other applications in semiconductor manufacturing. It features a compact design, addressing a wider spectrum of processes while maintaining effective utilization of space. The system accommodates gallium arsenide and other compound semiconductor wafers, as well as thinned silicon wafers, with its efficient wafer transport mechanism. The vacuum-isolated chambers minimize contamination risks, ensuring high-quality sputtering results. Integration with the upgraded Epoch controller enhances throughput and supports factory automation, making it a capable tool for manufacturing facilities seeking reliable and advanced PVD solutions.Plasma Dicing

Singulator - Plasma Wafer Dicing Systems

The MDS-100 and MDS-300 systems, branded under the Singulator name, are advanced plasma dicing solutions tailored for specific applications on tape frames. These systems are engineered to accommodate the challenges associated with dicing thin and ultra-thin wafers, offering precision and efficiency in the singulation process. The implementation of plasma dicing on tape (PDOT™) technology ensures enhanced performance while maintaining the structural integrity of the wafers. The Cortex® control system integrated within these models offers a stable and user-oriented interface which facilitates the handling and execution of complex processes efficiently. This system architecture prioritizes productivity while simplifying operational controls, making it suitable for volume production environments. By moving away from conventional dicing techniques, the MDS-100 and MDS-300 systems provide distinct advantages in precision, speed, and reduction of material stress.