Refine by

Pyrolysis Machines That Can Process Articles & Analysis: This-Year

17 news found

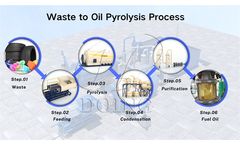

Pyrolysis is a thermal degradation process that breaks down complex polymer chains in the absence of oxygen. When applied to rubber, pyrolysis can convert waste materials such as tires or industrial rubber into valuable products such as fuel oil, carbon black, and steel wire. The process involves heating the rubber to a specific temperature, which varies slightly depending on the type of rubber ...

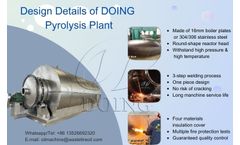

The cost of pyrolysis reactors is influenced by a range of factors, including reactor type, processing capacity, material quality, safety systems, and market factors. Below is an analysis of the key elements that impact the cost of pyrolysis reactors: Reactor Type and Design The design and type of pyrolysis reactors significantly affect their cost. Traditional reactors, such as those with partial ...

PVC (Polyvinyl Chloride) is rarely used in pyrolysis processes—whether for waste-to-energy, fuel production, or chemical recycling—due to severe environmental hazards, equipment damage risks, and poor economic viability associated with its chlorine-rich composition. Below is a detailed breakdown of the core reasons: 1. Releases Highly Toxic Chlorinated Compounds PVC contains ~57% ...

Chemical and Petrochemical Companies: Through oil distillation machines, pyrolysis oil can be further refined to extract high - value chemicals or used as a feedstock for producing synthetic fuels, plastics and other petrochemical products. ...

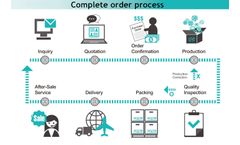

As a pyrolysis machine manufacturer, DOING Company is dedicated to delivering a smooth and efficient pyrolysis machine delivery process for our clients. ...

Pyrolysis equipment plant stands as an environmentally friendly recycling solution for waste. It not only curbs the pollution arising from waste itself but also eliminates secondary pollution throughout the recycling process. Pyrolysis equipment plant is an eco - friendly recycling approach that transforms various types of waste into fuel energy. On one hand, it can handle large volumes of waste, ...

Pyrolysis is a highly efficient method for recycling rubber products, especially those that are difficult to process using conventional mechanical recycling techniques. The method involves heating rubber in the absence of oxygen to break it down into valuable byproducts such as pyrolysis oil, carbon black, steel wire (in the case of tires), and non-condensable gases. Used Tires (Car, Truck, ...

As a leading manufacturer of pyrolysis plants, DOING Company is dedicated to providing innovative and efficient solutions for waste-to-energy conversion. Our pyrolysis technology not only helps in managing waste but also produces valuable oil products that can be utilized in various industries.Understanding the Pyrolysis Process Pyrolysis is a thermal decomposition process that occurs in the ...

This ensures that emissions meet strict environmental standards, making pyrolysis a clean and green waste processing option. ② Combustible Gas Purification System: Energy Recycling One of the standout features of DOING’s environmentally friendly pyrolysis machines is energy recycling. During the pyrolysis ...

The cost of a plastic to fuel pyrolysis equipment largely depends on its model, processing capacity, the configuration, etc. Therefore, it is important to consider these factors comprehensively when choosing a suitable plastic fuel pyrolysis equipment. DOING has researched plastic to fuel pyrolysis equipments for 14+ years, and our plastic to fuel pyrolysis equipment can be roughly divided into ...

It can be refined further with pyrolysis oil distillation machine to produce diesel that used in diesel generator and heavy machine. ...

Through an advanced pyrolysis process, used tyres will be converted into tyre-derived oil, which will then be refined into Sustainable Aviation Fuel and road fuels. This initiative is poised to achieve over 80 per cent reduction in life cycle carbon emissions compared to traditional fossil fuels. Expected to begin operations in 2026, the Sunderland facility will reach full capacity by 2027, ...

What Types of Waste Can the Machine Process? Understanding the range of organic solid hazardous waste materials a pyrolysis machine can handle is the first step in determining its suitability for your operations. Different waste types require specific processing conditions, and ...

In the realm of environmental recycling solutions, pyrolysis systems, also known as pyrolysis machines, plants, or equipment, have emerged as a crucial means to transform waste tires, plastics, oil sludge, and other discarded materials into valuable energy resources. As a trusted and seasoned manufacturer and supplier in the industry, Huayin takes pride in presenting a comprehensive lineup of ...

Pyrolysis and cracking are related processes, but they are not exactly the same. Here's a comparison: Similarities Decomposition nature: Both pyrolysis and cracking involve the decomposition of larger organic molecules into smaller ones. They are both thermochemical processes that occur under high - temperature conditions and in the absence or limited presence of oxygen. ...

In contrast, TPCB is derived from end-of-life tires through pyrolysis—a process that breaks down rubber at high temperatures without oxygen, yielding oil, gas, steel, and carbon black. ...

Youngstown council voted to extend the pyrolysis moratorium first passed last year. The vote resulted in applause from audience members, as the city does what it can to stop the company’s plans. In a stunning statement Youngstown Councilwoman Anita Davis stated; “There’s no other country that has a process like this. It’s so brand new. It’s experimental. I just ...