Pyrolysis Machines That Can Process Articles & Analysis

316 articles found

Oil sludge, a byproduct of the petroleum industry, is a challenging waste material that requires efficient disposal or treatment. One promising method for processing oil sludge is oil sludge pyrolysis, a thermal decomposition process that breaks down complex hydrocarbons into useful products like oil, gas, and solid residues. However, one crucial factor that significantly affects the efficiency ...

In the face of mounting global waste disposal issues and environmental pollution, the need for innovative waste management solutions has never been greater. Among the most promising technologies is pyrolysis, a thermal decomposition process that not only helps manage waste but also contributes to energy recovery and resource conservation. Pyrolysis technology is quickly gaining traction in the ...

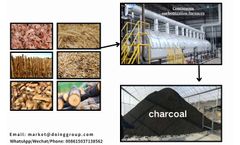

A charcoal maker machine converts biomass materials into high-quality charcoal through a high-temperature carbonization process. ...

By incorporating specialized catalysts into the pyrolysis process, industrial operators can significantly improve oil yield, enhance product quality, and optimize energy efficiency. ...

Pyrolysis Gas: This can be captured and used as fuel for the pyrolysis process itself or for sale to nearby industrial plants. ...

However, the quality of the carbon black produced during tire pyrolysis can vary based on several factors, and understanding these influences is essential for maximizing the value of the process. ...

Traditional methods often fail to meet the needs of large-scale continuous production of biochar, with low output, unstable quality, and huge impact on the environment. Continuous biomass pyrolysis machine DOING biochar carbonization reactor is designed for continuous operation and can quickly process large amounts of biomass. ...

Coconut Shell Charcoal: A Sustainable Resource Coconut shell charcoal is created through pyrolysis, a carbonization process that converts shells into clean-burning charcoal without oxygen. ...

The continuous pyrolysis equipment for plastic, tire, and oil sludge cracking has seen significant advancements in technology that offer improved efficiency, cost savings, and environmental benefits. Below are the three key technological breakthroughs that set this equipment apart: 1. Efficient Oil-Gas Condensation and Anti-Polymerization Technology This technology uses a direct spray mixing ...

In today's world, with the continuous improvement of environmental awareness and the growing demand for energy, biomass energy, as a renewable and clean form of energy, is gradually attracting global attention. With its advanced carbonization equipment, DOING is leading the innovation and development in the field of biomass energy, injecting new vitality into the global energy transformation. ...

The global environmental impact of industrial waste, particularly oil sludge, has become an increasingly pressing issue. The accumulation of oil-contaminated waste in landfills or open environments leads to severe soil contamination, adversely affecting soil quality, biodiversity, and agricultural productivity. However, advancements in pyrolysis technology offer a promising solution to alleviate ...

The reactor can process various feedstocks, including plastics, tires, biomass, and other organic materials. ...

This heat causes the shells to decompose, releasing volatile gases and producing solid biochar.The by-products of the pyrolysis process, including gas and liquid oil, are captured and can be used to generate energy for the system or sold for other purposes. ...

This reduces the need for fossil fuels and helps in the circular economy model by reintroducing waste into the production cycle. Pyrolysis gas, which consists of volatile hydrocarbons, can be used to power the pyrolysis process itself, thereby making the system more energy-efficient and reducing external energy needs. ...

Catalytic pyrolysis is a modified version of the traditional pyrolysis process. While traditional pyrolysis relies solely on heat to break down organic materials, catalytic pyrolysis introduces a catalyst into the reaction system. ...

Achieving the desired quality requires attention to various factors during both the production and processing stages. From raw material selection to machine efficiency, several strategies can improve the final product. ...

Biochar pyrolysis is a thermochemical process that involves heating biomass - materials such as wood, agricultural waste, or dedicated energy crops - in an oxygen - limited environment. As the biomass is heated to temperatures typically ranging from 300°C to 800°C, a series of complex chemical reactions occur. The biomass decomposes, releasing volatile gases like methane, hydrogen, and ...

Diversified Revenue Streams One of the most compelling reasons to invest in a biochar machine is the opportunity to create multiple revenue streams. The core product of the pyrolysis process—biochar—has a range of applications across various industries, including agriculture, environmental management, and energy production. ...

Larger machines, which can handle substantial amounts of biomass, require more robust components and greater engineering precision. ...

In fact, pyrolysis machines are designed to capture and utilize the gases produced during the process, reducing emissions and enhancing energy recovery. ...