Refine by

Resource Recovery Articles & Analysis

60 news found

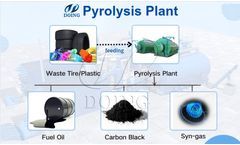

Pyrolysis and combustion are both methods to process organic materials like waste tires, plastic, or sludge, but they differ drastically in environmental impact, resource recovery, and efficiency. Pyrolysis—defined as the thermal decomposition of materials in the absence of oxygen—offers distinct advantages over combustion (burning in oxygen), making ...

This approach helps address the issue of waste glove disposal while maximizing resource utilization. Rubber Soles and Shoe Parts Discarded shoes, particularly soles made from synthetic or natural rubber, can be thermally decomposed through pyrolysis to recover usable materials. ...

This dual benefit of waste reduction and resource recovery is a remarkable achievement in sustainable waste management. ③ Less Waste Pollution Burden Compared to traditional landfilling or incineration methods, which can release toxic gases and waste valuable resources, pyrolysis machines effectively convert waste into usable substances like fuel ...

Nowadays, where waste management and resource recovery are of paramount importance, pyrolysis machine have emerged as a promising solution. ...

The U.S. is home to approximately: 609 anaerobic digesters on farms; 1,180 water resource recovery facilities using digesters; 113 stand-alone food waste systems; and 583 landfill gas capture projects. The industry’s growth potential is 500% greater, including: 11,200 livestock farms; 3,750 additional water resource ...

The $23 million project utilizes patented anaerobic digestion technology to support Vermont’s circular economy goals by minimizing waste and maximizing resource recoveries. PurposeEnergy – Middlebury is the state’s first food waste to renewable electricity project awarded under the Vermont Public Utility Commission’s Standard Offer ...

The LCFS, under the guidance of the California Air Resources Board (CARB), has proven essential in driving down greenhouse gas emissions, promoting cleaner fuel adoption, and supporting the state’s ambitious climate goals. ...

Greenlane Renewables Inc. (“Greenlane” or the “Company”) (TSX: GRN / FSE: 52G) is pleased to announce that it has filed two new patent applications for landfill gas upgrading technology. The Company intends to bring to market in 2025 a new compelling product line that incorporates the content of these patent applications architected to advance the state-of-the-art in the ...

Argonne's energy storage research focused on reducing dependence on critical materials, facilitating sustainable resource recovery, discovering new lower-cost and higher energy density materials and enabling safe fast charging will inform decisions as Michigan advances economic expansion in battery manufacturing and ...

Waste to energy is a part of the waste management hierarchy, which includes waste reduction, recycling, and energy recovery. By processing waste that cannot be recycled or reused, incineration reduces the need for landfill space and maximises resource recovery. ...

Versatility: Pyrolysis can handle a wider range of plastic types, including mixed or contaminated plastics, which are challenging for traditional recycling methods. B. Energy Recovery: Pyrolysis produces fuel products like oil and gas, which can be used as energy sources, thus reducing the need for fossil fuels. ...

Fully continuous waste tire to fuel oil pyrolysis processing lines are considered efficient and environmentally friendly solutions for waste tire disposal, as they not only help reduce the environmental impact of tire waste but also offer the potential for resource recovery and energy generation. Henan Doing Company is a leading and professional manufacturer who ...

Pyrolysis machines have gained significant attention as a sustainable solution for waste management and the production of valuable resources. One crucial aspect to consider when exploring this technology is the price of the pyrolysis machine. ...

Particularly in the face of increasingly stringent environmental regulations, pyrolysis technology holds promise as an excellent solution for resource recovery and energy conversion. However, with safety as the foundation, we can confidently embrace innovation and application in pyrolysis ...

As the demand for eco-friendly solutions continues to grow, pyrolysis technology stands as a beacon of hope in the realm of waste tire recycling and resource ...

This feedback and other information on the plan’s development can be found on the New York State Climate Act website, climate.ny.gov, along with an Executive Summary and additional resources. The Council’s seven Advisory Panels, along with the Climate Justice Working Group (CJWG) and Just Transition Working Group (JTWG), also submitted recommendations for consideration in the ...

As part of Schlumberger’s NeoLith Energy direct lithium extraction (DLE) and production flowsheet, Gradiant technology is used to concentrate the lithium solution and generate fresh water—a critical element in sustainable lithium production from brine. “Proper natural resource management is essential in mineral production, and nowhere more so than in ...

ByGradiant

EnviroWaste Services is a leading New Zealand based sustainable resource and waste recovery management company. Hampton PARRC (Power & Resource Recovery Centre) is located just south of Auckland, in the North Waikato and services a wide area from Auckland to the Bay of Plenty and Waikato. ...

During the IFAT 2022, hall A4, booth 251, econ will showcase innovative solutions that maximize resource recovery, efficiency and economical gains through CO2-free systems, enabling waste generators and disposal firms to be equipped not only for today but also for tomorrow. ...

Downey Ridge Environmental Company, developer of Greasezilla™ FOG separation and processing systems, announces that Sheltowee CleanTech Fund I, LLC, is investing over $8,000,000 to expand Greasezilla technology nationwide. Greasezilla will invest the capital to build ten new Greasezilla FOG receiving stations with private and public joint venture partners across the ...