- Home

- Companies

- ClearSign Technologies Corporation

- Products

- Clearsign Core - Boiler Burner ...

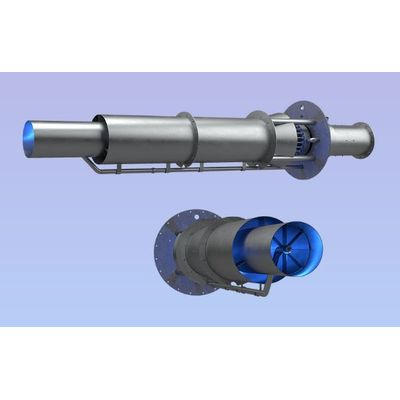

Clearsign Core - Boiler Burner Technology

Clearsign Core™ Boiler Burner Technology offers a cutting-edge solution designed to enhance the performance of both firetube and watertube boilers while significantly reducing emissions. It achieves ultra-low NOx emissions below 2.5ppm without relying on reagents, catalysts, or high excess air conditions. This is accomplished through a combination of premixed combustion, entraining spent flue gases, and a distal flameholder. The system supports a turndown ratio greater than 5:1 and maintains high combustion efficiency even at low excess air levels. The technology accommodates boiler capacities ranging from 4MMBTU/hr to 100MMBTU/hr, making it suitable for diverse industrial applications including agriculture, refining, and commercial sectors. Additionally, it enables seamless retrofitting without requiring changes to existing furnace cutouts, providing cost-effective upgrades. Clearsign's partnership with California Boiler ensures installation expertise, enhancing the system's integration and functionality for the industrial market.

Ultra Low NOx <2.5ppm

Premixed combustion, entrainment of spent flue gases, and a distal flameholder enable NOx levels never before seen in the industry – all without the use of reagents, catalysis and/or high excess air conditions.

Ultra Low CO <50ppm

Thorough premixing of the incoming fuel and air mixture ensures a highly efficient combustion at temperatures that ensure complete CO burnout.

Turndown >5:1

Increased combustion intensity and robust flame holding generate wide stability envelopes and ensure a high degree of turndown.

High Efficiency

Stable operation at low excess air levels ensures highly efficient combustion unlike competing high excess air solutions.

Capacity

ClearSign Core™ Boiler solutions have ranges from as low as 4MMBTU/hr and up to 100MMBTU/hr, a true testament to the breadth and scalability of the technology.

Retrofit Solution

Due to the burner arrangement, a conventional burner tile is not required, allowing the burner to increase fired capacity without the need to change existing cutouts in the furnace floor. This allows for quicker and less expensive retrofit / burner changeouts.