- Home

- Companies

- ChemTreat - Veralto

- Products

- ChemTreat - Heat Exchangers

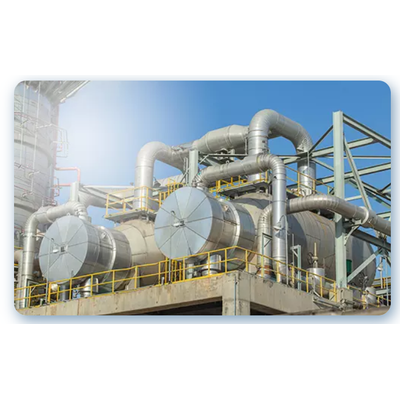

ChemTreat - Heat Exchangers

Heat exchangers remove unwanted heat and typically transfer it to a recirculating cooling water stream. While water-cooled heat exchangers are used most often (shell and tube, plate and frame), some heat exchangers are air-cooled.

Heat exchangers typically transfer unwanted heat to a recirculating cooling water stream. The cooling water temperature will be elevated as it absorbs heat from process and utility equipment, which is then expelled through partial evaporation of the water across a cooling tower. Several problems may arise in this heat transfer process as issues like corrosion, scale, fouling, and microbial growth will reduce flow rates and heat transfer rates and lower system efficiency.

ChemTreat field representatives can customize your cooling treatment program to ensure heat exchangers operate at peak efficiency and the cooling system effectively reduces the process fluid temperature. We have expertise in a variety of different heat exchanger designs including:

- Shell and tube

- Plate and frame

- Exposed tube