DSS - Model SCi DN40 – DN50 (1-1/2-2 Inch) - Venturi Steam Traps

The Delta SCi Venturi Steam Trap is designed for medium to large process applications including heat exchangers, reboilers, air heaters, etc. The Delta SCi has a removable venturi insert. A strainer can be fitted upstream of the trap.

- Threaded

- Medium to large process applications

- Energy Saving Steam Traps (watch video)

- Reduce boiler fuel costs by 20-30%

- Save steam, water and water treatment chemicals

- No moving parts to maintain

- Constructed completely from stainless steel

- Require no spare parts, testing or monitoring equipment

- No steam trap surveys required

- Guaranteed for 20 years

- Our steam traps are not consumables, they far outlast conventional steam traps

Delta venturi vs. conventional mechanical steam traps.

Our steam traps have no internal moving parts. Because we have no internal moving parts our steam traps do not fail and break and do not need to be repaired or require spare parts. Because our steam traps have no internal moving parts we guarantee our steam traps for 20 years on steam distribution lines and process applications. Our steam traps work on the principle of downstream flash steam to self-regulate the upstream condensate flow and allow condensate to be removed and keep the steam in the system.

Conventional mechanical steam traps all use some form of mechanical system to open and close. Some use an inverted bucket or a ball or bimetallic element or discs or thermostatic elements but they all use some form of moving part that allows the valve to open and close.

Because these conventional steam traps have mechanical parts, these valves open and close hundreds of times a day, thousands of times a month and millions of times a year.

After a period of time, these moving parts start to wear out and eventually they will break and then the conventional mechanical steam traps will start to leak large amounts of steam, which is both expensive and causes unnecessary pollution.

Delta steam traps are guaranteed for 20 years against failure and are more reliable than any conventional steam trap in the market.

- Removable venturi insert allowing superior sizing flexibility

- Deflective cone insert protects inlet from solids and blocking

- Constant discharge principal improves heat transfer

- 20 Year guarantee

This product fully complies with the requirements of the European Pressure Equipment Directive 97/23/EC as well as ASME B31.1 and B31.3 and SANS 347:2007.

Manufacturer’s test report is available with this product. Additional certification requirements to be stated at time of order.

- 20 year product guarantee as per standard terms and conditions.

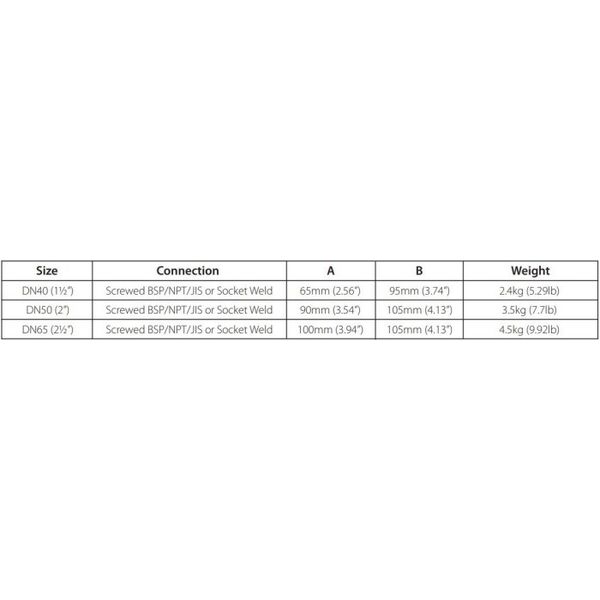

DN40 (1 ½”) - DN65 {2 ½”) Screwed (BSP/NPT/JIS) & Socket Weld

20 year product guarantee as per standard terms and conditions

20-Year Guarantee

Steam saving Delta Venturi Steam Traps advantages include that it comes standard with our 20-year product quality and performance guarantee.

Minimal Steam Trap Maintenance

- No Moving Parts

- No Spare parts required

- Permanently eliminate the need for steam trap surveys

- Savings on labour for repairing steam traps

- Unaffected by thermal shock or water hammer

- Efficient steam trap system enables a considerable steam saving

- CO2 emissions are reduced through reducing steam wastage through failed traps

- Save water

- Save water treatment chemicals

- Save boiler fuel (gas, oil, coal or electricity) by up to 30%

- Due to the traps unique DSV™ venturi orifice design there is TRUE continuous condensate discharge without any open/close cycles rather than intermittent discharge like traditional mechanical type steam traps such as ball float or inverted bucket traps.

- Upstream control valves have a more linear steam supply to the process equipment rather than the traditional continuous peak and trough supply.

- A thinner film of condensate is accumulated on the heating surface of the process equipment allowing improved heat transfer.

- Through permanently eliminating failed steam traps passing live steam into the condensate return system and pressurising this system, a more balanced downstream pressure is achieved allowing faster condensate discharge and improved heat transfer.

- Minimal thermal energy loss due to the Delta DSV™ Steam Traps compact design (in some cases up to 20 times smaller than mechanical steam traps)