- Home

- Companies

- HRS Process Systems Pvt. Ltd.

- Products

- Ecoflux - Corrugated Tube Heat ...

Ecoflux - Corrugated Tube Heat Exchanger

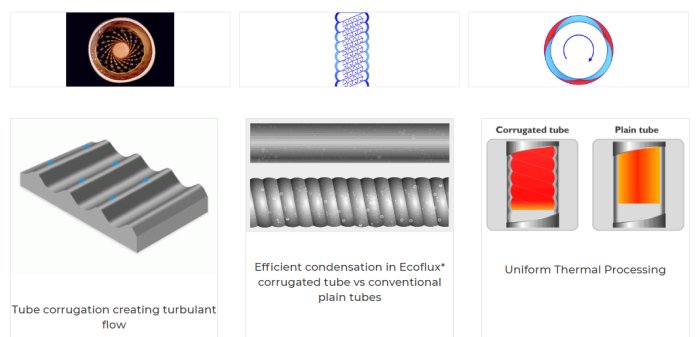

HRS is a pioneer in bringing the corrugated tube technology in heat exchangers. Our Ecoflux* Corrugated Tube Heat Exchangers (CTHE) are available in a range of models and materials, designed to increase the efficiency of processes. Use of corrugated tubes instead of smooth tubes ensures a compact and economical equipment with substantial reduction in fouling.

The development of corrugated tube is perhaps the most exciting advancement in heat transfer technology. Corrugations induce turbulence in the media and ensure high Reynolds number even at low velocity. Corrugations are made with specially designed patterns and in a manner where there is no tube wall thinning and the strength of the tube remains intact.

Corrugation imparts different flow regimes – spiral at the core and eddy’s at the periphery. The helical flow contributes to the situation that the fluid particles are alternatively in the vicinity of the tube wall and then in the main flow. Between the helical impressions, around the circumference of the tube, secondary flow, typically in the form of eddies occur.

The roughness elements need to have a minimum height so as to influence the flow and thus the heat transfer. To ensure that the heat transfer is improved by roughness elements, the flow must be influenced within the heat conduction layer.

The key for enhanced efficiency in corrugated tube heat exchangers is design of the tubes with minimal boundary layer resistance. This determines the various styles of tube corrugation: continuous spiral indentation or an intermittent spot indentation.

The continuous disturbance of the boundary layer of the tube side fluid increases the amount of turbulence within the fluid as described mathematically by the “Nusselt number” and, providing the tube side fluid has the higher resistance to heat flow, will increase the overall rate at which heat is transferred.

The flow regime in Ecoflux* Corrugated Tube Heat Exchanger ensures that the rate of decrease in boundary layer resistance exceeds the rate of increase in pressure loss. In other words high heat transfer coefficients with minimum increase in pressure drop.

Increase in heat transfer coefficient brings the temperature of the tube wall closer to the temperature of the bulk fluid on the tube.

-

Compact tubular heat exchanger

-

Long running times due to turbulent flow

-

Very low maintenance costs, minimum spares requirement

-

Higher heat transfer coefficient (2-3 times) results in reduction in heat exchanger area upto 50%

-

Fouling is minimized due to turbulence created by eddies at the periphery or tube wall

-

High response to CIP

-

Wide choice of MOC

-

Uniform thermal processing

-

More flexibility in annular space sizing

-

Custom-made to suit high pressure and temperature profiles

Ecoflux* Corrugated Tube Heat Exchangers are used across process industries for a host of applications. Thermal and mechanical designs, material of construction is determined as per process and product compatibility to give optimal energy efficient solutions.

In chemical, pharmaceutical, fertilizer, cement, biotechnology, power generation, food, drink, brewing, environmental processes Ecoflux* Corrugated Tube Heat Exchangers are used as vapour condenser, effluent cooler, exhaust gas cooler etc.

In food processing sector, as range of heating, cooling, condensing, sub-cooling, pasteurization, sterilization, evaporation, continuous cooking, heat recovery, etc. applications are enabled with corrugated tube heat exchanger based systems and turnkey lines for fruit pulp, beverage, dairy, nutraceuticals, probiotics, ready-to-eat foods, purees and concentrates and diced food processing.

In environmental and sanitary hot water processes, effluent treatment, digestion sludge, effluent water, along with power generation and latex industries, corrugated tube heat exchangers are used in various heating, cooling applications.