Cleaver-Brooks

- Home

- Companies

- Cleaver-Brooks

- Products

- Cleaver Brooks - Model Max-Fire Series ...

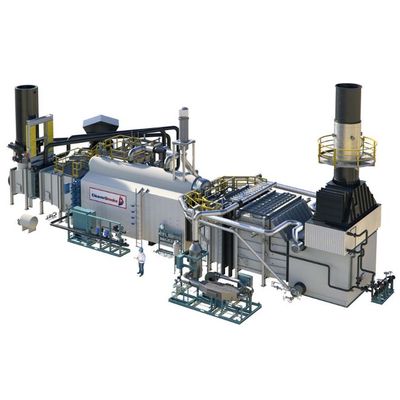

Cleaver Brooks - Model Max-Fire Series -Heat Recovery Steam Generators (HRSG) Boiler

FromCleaver-Brooks

The Cleaver-Brooks Max-Fire boiler incorporates an integral furnace in a single shop-assembled package heat recovery steam generator (HRSG) that combines a furnace and evaporator and superheater, if applicable, with a natural circulation design. Capable of steam flows up to 500,000 lb/hr, the Max-Fire Series is offered in two different models. The MF (O-style) and MFA (A-style) models combine the waterwall combustion chamber formed from membrane wall construction with an evaporator section in a single shop-assembled boiler. The VL (O-style) and VLA (A-style) models offer an evaporator section without a furnace, but still enclosed with membrane wall construction.

Most popular related searches

heat recovery steam generator

heat recovery steam generation

heat recovery steam

steam generation

steam generator

heat recovery

combined heat and power

heat and power

heat recovery boiler

combustion chamber

- Gas flows up to 1,000,000 lb/hr

- Steam Generation from 10,000 to 500,000 lb/hr

- Design pressure up to 2,300 psig

- Steam temperature to 1,050 °F

- Supplemental firing with stack emissions available to less than 2 ppm NOx with SCR

- The Cleaver-Brooks Max-Fire® boiler incorporates an integral furnace in a single-shop assembled, packaged HRSG design. The use of the membrane/water-cooled furnace technology allows it to be fired up to 2800°F while avoiding the use of high-maintenance refractory.

- The Cleaver-Brooks HRSG achieves >80% efficiency compared to 56% for traditional technologies. It reduces up to 7.0 MMBtu/hr of fuel in conventional boilers and eliminates 2,870 tons of CO2 emissions annually per 1 MWe GT output.

- Completely shop-assembled boiler with integral water-cooled furnace utilizing membrane-wall construction for firing temperatures up to 2800˚F.

- Vertical (top) and horizontal gas outlet for meeting tight space requirements.

- Combination bare and finned tube sections to provide efficient heat recovery.

- Multiple finned-tube designs for optimized heat transfer.

- Large steam drums to assure ample steaming area.

- Hard or aluminum casing

- Downcomers on both ends of the boiler.

- Accommodation for selective catalytic reduction (SCR) and CO catalyst.

- Combined Heat and Power

- Process Steam

- District Heating

- Universities and Institutions

- Steam Heating

- Hospital and Healthcare

- Chemical

- Power and Utilities

- Refineries and Petrochemical

- Wastewater Treatment

- Assembly: Shop Assembled

- Construction: Membrane Wall Construction

- Exhaust Gas Flows (lb/hr): Up to 1,000,000

- Steam Flows (lb/hr): Up to 500,000

- Type: HRSG

- Circulation: Natural Circulation

- Duct Firing Temperature: Up to 2,800 deg F

- Gas Turbine Size: 3 MW - 25 MW

- Steam Temperature: Up to 1,050 deg F