- Home

- Companies

- Lectrodryer, LLC

- Products

- Lectrodryer - Model HPS - Hydrogen ...

Lectrodryer - Model HPS -Hydrogen Purification System

The HPS Lectrodryer is specially designed for purifying hydrogen process gas streams generated by electrolysis. The HPS Lectrodryer can be used with all methods of hydrogen production and optimized for the generation method.

Current designs pair with electrolyzer sizes from pilot scale to 250MW. Removal of moisture and other contaminants like oxygen allows the hydrogen product to meet ISO 14687, SAE J2719, and other hydrogen quality standards. Dual tower, heat-reactivated design allows for continuous operation and purification. The closed-circuit design utilizes a captive volume at line pressure so no loss of process gas is required for reactivation of the adsorbent.

One column of the dual tower purifies the hydrogen gas as it passes through the adsorbent bed, then the process switches to the other column while the first column reactivates. While the captive volume is circulated, the closed system removes the condensable materials driven off the adsorbent. Reactivation is done by means of a motor-driver blower that circulates the captive gas through a heater and adsorbent tower. The desorbed moisture will be condensed by a water-cooled inner cooler and then separated and trapped for removal.

- Containerized ready skid

- Catalytic Deoxygenation Reactors

- Oxygen Analyzer

- Inlet Heat Exchanger

- On-board Chiller System

- Inlet Hydrogen-Water Separator

- Pneumatic or Electrical Actuation

- DCS Control Option

- International Certifications

- Containerized ready skid

- Catalytic Deoxygenation Reactors

- Oxygen Analyzer

- Inlet Heat Exchanger

- On-board Chiller System

- Inlet Hydrogen-Water Separator

- Pneumatic or Electrical Actuation

- DCS Control Option

- International Certifications

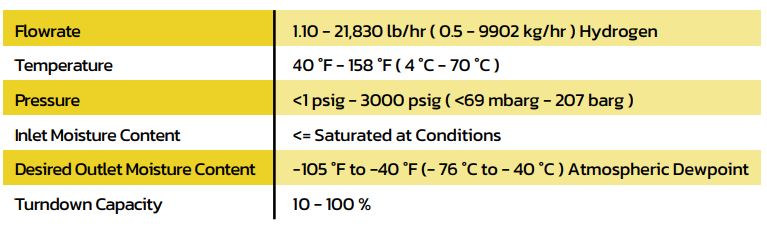

The selection of a particular HPS Lectrodryer is more complex than the selection of a traditional dryer system. Because of the complex nature of the selection, each Lectrodryer should be handled individually so the right model can be selected for the application. Typical, but not limited to, application conditions: