Koch Heat Transfer Company

- Home

- Companies

- Koch Heat Transfer Company

- Products

- KOCH Hairpins - Double Pipe and ...

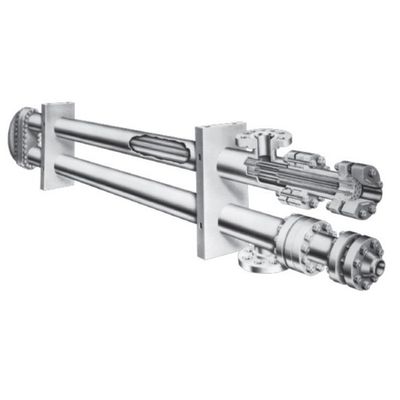

KOCH Hairpins - Double Pipe and Multitube Heat Exchangers

Koch Heat Transfer hairpins are the industry standard for efficient performance and proven reliability. Backed by more than 300 years of combined engineering and manufacturing experience, our innovative designs and unique closures are a key element of more economical designs that offer ongoing operational savings. Learn more about putting the industry-leading expertise of Koch Heat Transfer and the performance advantages of our hairpins to work for you.

Most popular related searches

- Cost Effective : In many applications, performance can be achieved by a single hairpin as opposed to multiple Shell & Tube exchangers, resulting in lower capital costs, as well as future maintenance.

- Cyclic or Shock Service : Large-radius U-bends and all terminal connections located at the same end allows for more extreme thermal expansion without the need for an expansion joint.

- Durable Baffle Cage : Baffles are welded to tie rods without “sleeves” or internal nuts.

- Extreme Terminal Temperature Differential : Independent-tube sheets and closure components eliminate differential thermal expansion across a single-tube sheet design, as is typically encountered with conventional Shell & Tube.

- High Pressure : Our unique closure technology allows for pressures exceeding 10,000 psi.

- Large-Radius U-Bends : Easy to clean, and eliminates the need for expansion joints or packed joints.

- Moveable Support Brackets : Allow shell expansion and contraction; eliminate sliding plates; slotted on all four sides for flexible installation and future additions.

- Separate Tube Sheets : Handles high temperature differences and cycling more effectively.

- Small Footprint : Due to the geometry of hairpins, the equipment takes up less space relative to the Shell & Tube alternative.

- Temperature Cross : Ideal when a temperature cross exists, or a close temperature approach is desired due to its single-pass configuration that allows for true countercurrent flow.

- Enhancement Devices : The use of Koch Heat Transfer enhancement devices, such as inserts, baffles, and TWISTED TUBE® Bundle technology can increase the effectiveness of engineered equipment.

- External Bolting :The external bolting allows for tightening of bolts while in operation without having to remove any covers or the tube bundle.

- Internal Terminal Closure : The independent closures on both shell side and tube side result in smaller flange designs. Our unique closures allow for more economical and efficient designs.

- Robust Aftermartket Support : Koch Heat Transfer maintains a dedicated aftermarket support staff that is available for your repair, replacement, and spare part needs.

- Single-Pass Design : The single-pass design allows for even distribution of expansion forces across the tube sheet.

- Wide Range of Sizes : Hairpins are a versatile product with compact designs that are typically more effective than large Shell & Tube designs. Sizes range from 2” O.D. to 40” O.D. shell legs.

- Fuel gas heaters

- Lean - rich glycol exchangers

- Lean - rich amine exchangers

- Lean - rich CO2

- Gas coolers

- Well stream heaters

- Intercoolers

- Aftercoolers

- Heat Affluent Exchangers