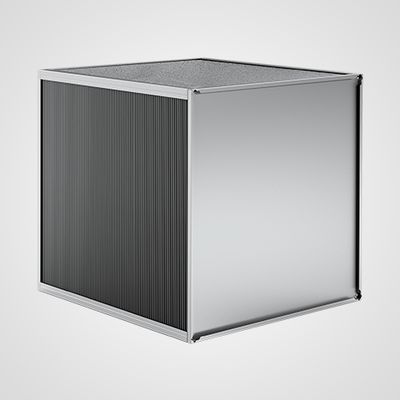

Model H2 -Cross Flow Heat Exchangers

Model H2 is our most efficient cross flow plate heat exchanger. It combines low-weight with high differential pressure resistance and is able to reach typical dry temperature efficiencies above 80%. The efficiency is improved by its slim profiles and our latest patented plate design, creating high turbulence even at lower velocities while keeping pressure drop low. Model H2’s performance is certified according to Eurovent, AHRI and TüvSüd. It can be configured to comply with Ecodesign 1253/2014 requirements. All Heatex cross flow plate heat exchangers meet several hygiene requirements.

We offer a wide range of options to suit various application and performance requirements.

Heatex Model H2 cross-flow heat exchangers are used in a wide area of applications.