- Home

- Companies

- Machine X Tech Corporation Limited

- Products

- Multi-Functional Coating Machine

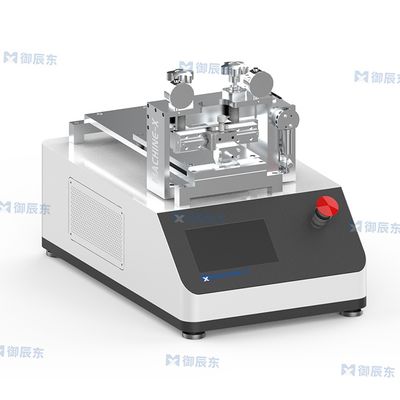

Multi-Functional Coating Machine

The coating process of nano and sub-micron level functional coatings is realized by flat plate coating, which is suitable for laboratory research and development, small batch trial production and process research, etc. It is suitable for coating of Calcium Titanium Ore Thin Film Solar Cells, Organic Solar Cells, Optical Films, and PI Films. 1. Small footprint of the equipment, convenient for different scenes; 2. Slit, scraper multiple coating mode integration, applicable to different coating needs; 3. Rich configuration, can be configured according to the needs of the heating platform, heating die head, coating process monitoring function; 4. Integrated high-precision feeding system, reducing solution waste; 5. Customized setting of coating parameters according to customer needs, coating process research is convenient; 6. Support customized solutions.The coating process of nano and sub-micron level functional coatings is realized by flat plate coating, which is suitable for laboratory research and development, small batch trial production and process research, etc. It is suitable for coating of Calcium Titanium Ore Thin Film Solar Cells, Organic Solar Cells, Optical Films, and PI Films.

Overall Dimension: 615*360*436mm

Voltage: Single-phase voltage AC220V±10%; Frequency: 50HZ

Coating area: 13*13mm~100*100mm

Viscosity of slurry: 1~100cps

Coating speed: 1~40mm/s(according to the nature of pulp)

Thickness of dry film: 0.05-10um(according to the nature of pulp)

Feeding pump precision: ≤0.5ul/s

Coating method: Slit/Scraper(based on demand)

Slit height adjustment range (die lip to substrate): 5mm

Temperature of material table: Room temperature~100℃

1. Small footprint of the equipment, convenient for different scenes;

2. Slit, scraper multiple coating mode integration, applicable to different coating needs;

3. Rich configuration, can be configured according to the needs of the heating platform, heating die head, coating process monitoring function;

4. Integrated high-precision feeding system, reducing solution waste;

5. Customized setting of coating parameters according to customer needs, coating process research is convenient;

6. Support customized solutions.