- Home

- Companies

- Megaunity Air System Co., Ltd.

- Products

- Megaunity - Plate-Fin U-Shaped Heat ...

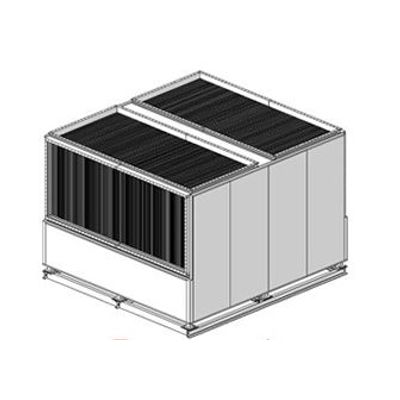

Megaunity - Plate-Fin U-Shaped Heat Exchanger

Plate-fin heat exchangers feature an extended secondary heat transfer surface, which consists of fins. Consequently, the heat transfer process takes place not only on the primary heat transfer surface (the plates) but also on the secondary heat transfer surface (the fins). The heat transfer area of the fins typically accounts for approximately 67% to 88% of the total heat transfer area of the heat exchanger. In addition to the energy from the high-temperature side gas transferring to the low-temperature side gas across the primary surface, it also propagates along the height of the fins and transfers energy to the plates. The plates then transfer this energy to the low-temperature side gas. Through continuous energy exchange between the high and low-temperature sides, energy exchange is achieved.

Product Types and Selection:

- Crossflow heat exchanger: Various installation methods, including diamond and horizontal placement. Customizable for different finned heat exchange efficiency ranging from 60% to 80% and pressure loss ranging from 300 to 1000 Pa.

- U-shaped heat exchanger Features a dual-core structure, capable of handling large airflows with heat exchange efficiency ranging from 60% to 90% and pressure loss ranging from 500 to 1200 Pa.

- All materials comply with RoHS/Reach environmental requirements, making the product more conducive to human health and environmental protection.

- Utilizes high-quality materials that meet national standards, offering excellent corrosion resistance and formability.

- Utilizes specialized calculation software and professional design software to meet various customer requirements for selection, providing optimal configuration solutions, and generating selection reports to improve design efficiency.

- Modular product manufacturing with no moving parts, easy to use, and low equipment maintenance costs.

- Welding technology is used on the airflow inlet edge, and it undergoes pressure testing before leaving the factory to ensure no leakage.

- Enhanced fin forming technology improves heat transfer efficiency and reduces pressure loss.

- Compact structure that can meet a broader range of customer needs and applications, capable of stable long-term operation.

- Diverse product types and flexible layouts to provide high-quality solutions for customers.