Raymond Flash Dryers

Proven Equipment for Your Drying Needs. Raymond flash dryers are simple to operate and well known for high on-line availability. Designed for use with fine, low to moderately abrasive, non-metallic, sticky, and heat sensitive materials, as well as for flash calcining applications. Raymond flash dryers have been providing processing solutions for the chemical, petrochemical, ceramic, pharmaceutical, food, fertilizer, plastic and other industries worldwide.

The Raymond Flash Drying Process

Flash drying is the rapid removal of moisture from mesh and micron sized solids that give off moisture easily, primarily as surface water. The wet material is dried by conveying it in a high velocity hot air stream. The short retention time in a flash drying system provides for maximum control of product quality.

Raymond Flash Drying Systems

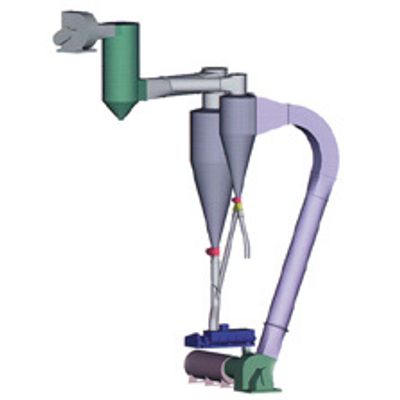

The essential components of a basic flash drying system are an air heater, feeder for introduction of the wet material, drying column, cyclone collector, secondary dust collector, vent fan and connective duct work.

Raymond flash dryers are provided with automatic temperature, pressure and electrical controls, with burner systems capable of firing natural gas, propane and/or oil.

Raymond flash dryers can also be combined with other functions such as pulverizing, separation, classification and conveying for use in additional process applications.

Various Arrangements

- Air Stream Flash Dryers: designed to bring wet dispersable products into contact with a heated high velocity gas stream.

- Cage Mill Flash Dryers: utilized with wet, lumpy and dispersable products where the agitation and turbulence created by the cage mill assists in drying of surface moisture.

- Imp Mill Flash Dryers: selected when size reduction of the process material is also required.

- Flash Calciners: provided when higher product temperatures are required to drive off chemically bound water.

- Flash Coolers: appropriate when high temperature process materials need to be cooled and transported to an elevated silo or storage bin.