- Home

- Companies

- Schmid Energy Solutions

- Products

- Schmid - Model UTSW - Moving Step Grate ...

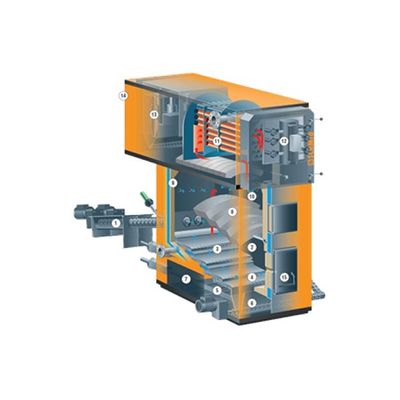

Schmid - Model UTSW -Moving Step Grate Firing System

Fuels with an extremely high calorific value or low ash melting point, such as particleboard waste, old timber, corn, rice husks.

- Operating medium : water / hot water / steam

- Grate cooling : water

- Operating range : 300 - 4200 kW

- Capacity regulation : modulating

- Water content : M 8 - 44

- Fuel types : scrap wood / residual wood / pellets / alternative fuels

- Furnaces for special fuels such as grains/corn, etc.

- Crushed wood

- Pellets and industrial pellets

- Particleboard furnaces in the wood processing industry

- Fuel supply with stoker screw

- Combustion chamber with water cooling

- Water-cooled step grate

- Burnout zone

- Under-grate de-ashing – automatic or manual

- Automatic grate ash discharge

- Access door to under-grate

- Radiation vault

- Refractory concrete with defined heat passage

- Secondary combustion chamber – in accordance with low NOx process by means of air stages

- 3-pass steam boiler

- Boiler door with automatic pulse-jet cleaning system of the boiler tubes

- Flue gas cleaning by multi-cyclone with automatic fly ash discharge

- Flue gas fan – can be positioned either on the right, left or at the rear

- Grate door with safety lock

The UTSW boiler unit is equipped with a step moving grate and also suitable for fuel with a high ash content. The fuel is fed on to the sloping feed grate from the rear of the furnace. The grate consists of water-cooled grate girders; the rods overlap on both sides, so that the minimum fuel slips through the grate. Furthermore, the grate is designed to enable a clear, uniform distribution of the primary air supplied to the various zones, thereby creating a steady, undisturbed gasification zone. The grate carriage has a hydraulic drive, so that the movement intervals can be automatically adjusted to the capacity. The entire combustion chamber is water-cooled and lined with fireproof material, thereby ensuring the required cooling even in the case of fuel that generate a high temperature in the combustion chamber.