- Home

- Companies

- Henan Greatwall Machinery Co., Ltd.

- Products

- Greatwall - Shaft Kiln

Greatwall - Shaft Kiln

As an experienced lime kiln manufacturer, we offer shaft kiln for lime production lines, the lime shaft kiln is the most efficient & ecological way to calcine limestone for lime production. 10% energy-saving, 20% yield improvement.

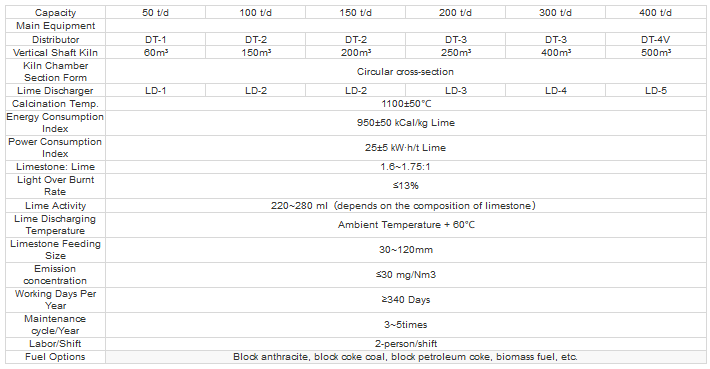

Processing Capacity: 50-400t/d

Max. Feeding Size:30-120mm

Application Fields: Vertical shaft kiln is suitable for metallurgy, building materials, calcium carbide, nano-calcium carbonate, aerated concrete, sugar, and other industries.

Applied Materials: Limestone, clay, high alumina clinker, dolomite, magnesium stone, and cement clinker, etc.

Customized Service:We can customize lime kilns and lime production lines, including active lime production line and hydrated lime production line, as per customers` need and offers technologies and services to help customers save energy and improve raw material efficiency.

Introduction of Shaft Kiln for Lime Production Line

The shaft kiln for lime calcination is the most efficient and ecological way to calcine limestone for quicklime production.

Adopting modern technology, our lime shaft kiln can make full use of cheap energy, especially the gas that pollutes the environment, such as converter gas, blast furnace gas, calcium carbide furnace tail gas, etc., as the main energy source, turning waste into treasure.

Compared with a rotary kiln, a lime shaft kiln is vertical cylindrical cylinder equipment with an all-steel structure and uses the principle of heat exchange between material self-weight descending and hot gas rising to carry out lime calcination.

1. 10% Energy-saving to save money and improve yield by 20%.

- Inside the limestone shaft kiln, from top to bottom, there are preheating zone, calcination zone, and cooling zone. The cooling air blows into the kiln from the bottom of the cooling zone. After heat exchange, the product is cooled, the cooling air is preheated, and the cooling air carrying heat enters the calcination zone to participate in combustion, thereby reducing energy consumption;

- The hot flue gas enters the pre-heating zone to preheat the material at room temperature to the pre-decomposition temperature. The temperature of the flue gas drops to 170-300°C before exiting the shaft kiln.

- The kiln shell is built with vertical masonry with four layers of refractory materials, which has a good thermal insulation effect. The temperature of the lime kiln shell can be controlled at about 60°C higher than the ambient temperature, and the energy saving is remarkable.

2. Long lifetime to save on the interrupted loss of production because of downtime costs.

- The refractory material has a long service life, and the material does not directly collide with the refractory material on the working surface but rubs against the working surface by gravity settlement, which reduces the wear rate of the refractory material;

- Under normal circumstances, the refractory material can be used for 6 to 10 years.

3. Multi-fuel options

- Co-fired kilns can be fuelled through lump coal and coking coal;

- Gas-fired kilns can be fuelled through high-calorific value fuels such as natural gas, coke oven gas, and petroleum gas, as well as low-calorific value fuels, such as converter gas, blast furnace gas, calcium carbide furnace tail gas, semi-coal gas, producer gas;

- Oil-fired kilns can use liquid fuels such as heavy oil and diesel as fuel.

4. Less floor space

- The vertical layout of the shaft kiln;

- Single-bucket hoist for feeding materials at a large angle;

- The layout of each functional area is compact.

5. Low investment

- Fewer machined parts for the steel structure of the kiln body, lower processing costs;

- Easy installation and low difficulty in masonry with refractory materials.

The shaft kiln is a cylindrical kiln body, the limestone is fed from the top of the kiln, and discharged from the bottom of the kiln after calcination.

According to the temperature change and distribution in the shaft kiln, the shaft kiln is divided into three sections from top to bottom: preheating section, calcination section, and cooling section.

The shaft kiln is a cylindrical kiln body, the limestone is fed from the top of the kiln, and discharged from the bottom of the kiln after calcination.

According to the temperature change and distribution in the shaft kiln, the shaft kiln is divided into three sections from top to bottom: preheating section, calcination section, and cooling section.

Combustion-supporting air is blown into the kiln from the lower part of the kiln body by the Roots blower, and rises from the lower part to the top of the kiln overcoming the resistance of the material particles.

Under the suction of the dust removal-induced draft fan, the flue gas is transported to the dust collector through the pipeline for dust removal.

Due to the action of the induced draft fan, a slight negative pressure zone (about -10Pa) is formed above the material surface in the kiln. This slight negative pressure ensures smooth airflow in the furnace, which is very beneficial to the decomposition of limestone with calcination. The induced draft fan will introduce all the flue gas into the dust collector for purification, and then discharge it into the atmosphere from the chimney up to the standard.