- Home

- Companies

- Guntamatic Heiztechnik GmbH

- Products

- Powerchip- Cascade - Model 100 - 400 kW ...

Powerchip- Cascade - Model 100 - 400 kW -Wood Chip Boilers

With the GUNTAMATIC cascade you will benefit from the highest reliability and economy. The proven step grate technology employed by the Powerchip boilers matches the boiler output to the current heat demand. This series satisfies even the highest output and quality requirements.

Major economical and ecological benefits can be achieved, particularly in the higher output range. GUNTAMATIC systems are not only CO2-neutral they are also exceptionally frugal in their consumption. GUNTAMATIC cascade systems are distinguished by their high level of reliability and their flexible output adjustment. Quality that speaks for itself.

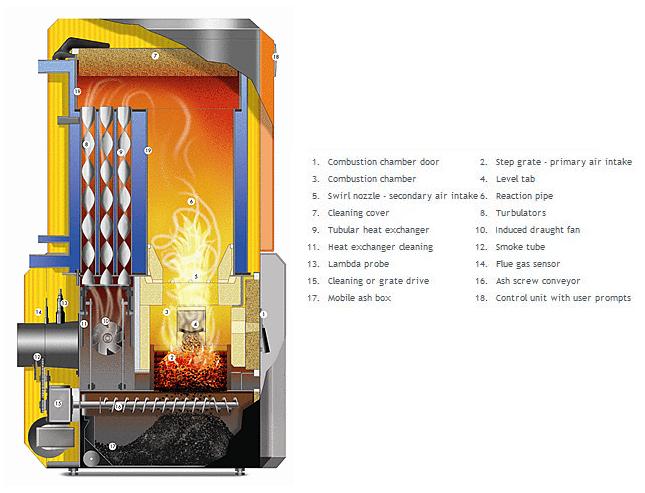

A clever control program starts the hot air fan quickly and efficiently. Fuel is perfectly consumed at the ideal combustion chamber temperature of around 650 °C. A self-cleaning step grate ensures the necessary movement in the incandescent bed as well as the ash removal. The combustion gases generated are cleanly converted to energy in a large burnout zone with the aid of a secondary air supply.

The extremely robust room discharge screw conveyor with sprung arm agitator transports wood chips, grain, miscanthus or pellets carefully and with the least possible expenditure of energy. Durable gearboxes and motors ensure the highest operational reliability. The unique modular system makes system transport and assembly easier.

A slow moving ash screw conveyor removes the grate ash into an extremely large mobile ash container. The dust from the heat exchanger cleaning process is also continuously removed into a container that is easy to empty. Options: Vacuum ash discharge with 200 l ash drum for fully automatic transport over a distance of up to 20 m.

- Regulated incandescent bed temperature: Perfect ash formation, no slag formation

- Self-cleaning step grate: The incandescent bed can be changed, subject to fuel

- Stainless steel cyclonic combustion chamber: Perfect dust separation, corrosion prevention

- Advanced microprocessor control: Automatic ignition and output reduction down to 7 kW, Lambda probe, weather-compensated control for up to 6 mixer circuits, optional remote control via mobile phone

- Highest convenience: Automatic grate and heat exchanger cleaning (mobile ash box to be emptied only approx. every 2-3 months)

- Lasting quality: Extremely robust agitator and screw conveyor design, gearboxes and motors of the highest quality, silicon-carbide combustion chamber, stainless steel linings

- Low power consumption: Pioneering discharge technology

- Flexible: Combustion of wood chips, miscanthus, pellets, grain as fuel and farm-grown fuels with a seasonal efficiency [to DIN] of > 94%.