- Home

- Applications

- europe

- coal fire

Show results for

Refine by

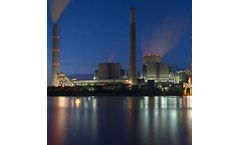

Coal Fire Product Applications In Europe

10 applications found

A coal-fired power plant in India, Hidalco Industries, needed a sure-fire way to detect the flow or no-flow of coal from the feeders to the furnaces. A plugged chute or equipment failure would possibly go unnoticed until a more serious problem occurred. Knowing whether the coal was positively feeding into the furnaces was of paramount importance to the efficient operation of the power plant. How can a ...

ByMonitor Technologies, LLC based in Elburn, ILLINOIS (USA)

Coal-fired power plants, waste incineration power plants, oil refineries, natural gas facilities, ...

ByHorizon Tek Services based in , UNITED KINGDOM

Power Plants, whether they be nuclear, coal-fired or gas-fired, require large quantities of water in the condenser to cool the steam which has passed through the ...

ByE. Beaudrey & CIE. based in Paris, FRANCE

Co-firing is the (partial) substitution of fossil coal by biomass in coal-fired power plants. Torrefied biomass offers the most cost-effective route to significantly increase the use of biomass as a renewable energy source and to reduce the CO2 footprint of industrial coal ...

ByBlackwood Technology B.V based in Hoofddorp, NETHERLANDS

Power Generation Combustion Air Measurements: The need for accurate, repeatable & reliable combustion air measurements in power generation plants is critical to efficient operation and safety throughout the entire facility and processes. Coal-fired power plant applications pose a number of challenges to obtaining these critical flow measurements includ¬ing large ducts, limited metering runs, poor velocity and temperature profiles, high vibration, temperatures up to ...

ByKurz Instruments, Inc. based in Monterey, CALIFORNIA (USA)

In the process, conventional fuels such as oil, natural gas, hard coal or brown coal are used to fire the steam boiler. In coal-fired power plants, coal is the only fuel used, whereas waste incineration facilities can also use treated waste in order to generate electricity. ...

ByJ.P. Sauer & Sohn Maschinenbau GmbH based in Kiel, GERMANY

Without controls, the combustion of solid fuel (coal) to generate power results in the emission of carbon dioxide (CO2), sulfur dioxides (SO2), nitrogen oxides (NOx), particulate matter, mercury, lead, cadmium, carbon monoxide, volatile organic compounds (VOCs), and arsenic. This is why it is critically important for solid fuel power plants to comply with stringent environmental standards by utilizing the optimal technologies for emissions management, environmental air pollution control, and fluid handling and ...

ByCECO Environmental based in Addison, TEXAS (USA)

...

ByAMETEK Process Instruments based in Pittsburgh, PENNSYLVANIA (USA)

Premium

Power plants are expected to operate 24 hours per day, 7 days per week. Downtime and equipment derating (when a generator fails to deliver power at its rated capacity) can cost a power plant thousands of dollars per hour. The cost of replacing failed equipment is also extremely high. Vibration analysis by itself is not enough to anticipate catastrophic failures. Oil analysis is often able to detect problems at a much earlier stage than vibration analysis. This is why more and more power plants are bringing oil ...

ByAMETEK Spectro Scientific based in Chelmsford, MASSACHUSETTS (USA)

For more than 25 years, coal and biomass fired plants have formed the largest installed user base for Procal CEM systems. ...

ByProcal - Parker Hannifin Corp based in Peterborough, UNITED KINGDOM