Coal Processing Articles & Analysis

20 articles found

Coal processing or coal beneficiation uses physical (mechanical) and/or chemical methods to remove rocks, dirt, ash, sulfur and other contaminants and unwanted materials to produce high-quality coal for energy in local and export markets. ...

Coal washing is a process through the impact of water flow, raw coal with different components and specific gravity is separated into different grades. It can remove dust and waste rock and reduce the ash and sulfur content. Coal washing is an indispensable link in coal processing. The ...

HDPE Pond Sheet Liner for Coal Chemical Industry in Indonesia Coal chemical industry refers to the conversion of coal into gas, liquid and solid through chemical processing using coal as raw material, Bulk fuel and chemical processes. It mainly includes coal gasification, ...

Application Area: Iron & Steel Industry Process: Coal Injection Measuring Components: O2, COApplication Scenario: Pulverized Coal Injection is the key to optimizing the blast furnace process for high productivity as well as hot metal cost. In this process, the raw coal is fed into the ...

The industrial honeycomb coal briquette production line is a series of equipment for deep processing coal powder and charcoal powder, mainly crushers, mixers, coal briquettes forming machines, and dryers. Through this briquettes charcoal processing plant, we can make coal powder and charcoal ...

The industrial honeycomb coal briquette production line is a series of equipment for deep processing coal powder and charcoal powder, mainly crushers, mixers, coal briquettes forming machines, and dryers. Through this briquettes charcoal processing plant, we can make coal powder and charcoal ...

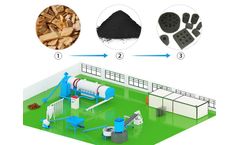

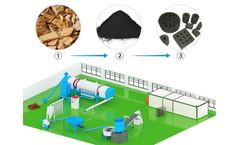

Industrial charcoal processing equipment is essential for the modernization of charcoal production. ...

How To Deal With Biomass Waste Making bio-coal briquette: Bio coal briquette as a kind of fire briquette can increase the energy density on volume, make it easier to transport or storage, also reduce the cost of these processes. ...

The first milestone of the working plan consisted in the definition of a three-flux low-NOx 35MW clean coal burner. The design process started with the definition of the design principles to be followed along with the coal and flame pattern to be achieved. ...

Burning of coal nowadays has become a big problem. The main reason for this is a rapid increase of mankind. So, China burns half of coal in the world. Since 2000 the share of coal in world energy production has increased from 25 to 30%, and the Chinese economy is responsible for 82% of this growth. ...

In an other part of the plant brown coal is refined and processed to briquettes and coal dust. For the processing of brown coal into briquettes different process steps are necessary. After its delivery the coal is screened and refined. There after it is prepared for the ...

ByENVEA

We developed a new calcination method to convert coal gangue (CG), a common waste generated from coal production process, into a modified form, which could be used as an adsorbent to remove Mn2+ from aqueous solution. Sodium tetraborate (Na2B4O7·10H2O) was added into the CG calcination process as an additive, and the ...

Bio coal Briquettes are made from biomass which is easily available and the briquetting process is cheaper than any other renewable energy producing process. Briquetting process is also very easy and only 4-5 people are needed in this process. Bio coal briquettes are easy to store and transport ...

In this study, oil agglomeration process has been employed to clean indigenous coal under the influence of parameters such as oil type, particle size and the pH value of aqueous medium. ...

Tea manufacturing industries in India use natural gas, tea drying oil, wood, and coal for process heat. India is the second largest producer of tea [(1,137.07, China 1,761.00) million kilogram] in 2012. About 0.6–1.2 kg of coal is required to produce one kilogram of dried tea with average moisture of 2.5–3 percentage (w.b.). ...

Coal-water fuel production process consists of three main phases: First phase – preliminary disintegration to the fraction size 3-12 mm. ...

Clarke Energy has signed a deal with Australia Pacific LNG to provide a 30MW temporary power plant to their coal seam gas processing plant in Queensland. Clarke Energy to provide 30 MW temporary power station to support operation of Reedy Creek coal seam gas processing facilities Australia Pacific LNG, a joint venture between ...

Addressing the environmental risks related to contamination of groundwater with the phenolics, benzene, toluene, ethyl benzene, xylene (BTEX) and polycyclic aromatic hydrocarbons (PAHs), which might be potentially released from the underground coal gasification (UCG) under adverse hydrogeological and/or operational conditions, is crucial in terms of wider implementation of the ...

TenCate helps North River Mine continue processing coal by utilizing first ever large-scale Geobag disposal method. In 2007, the North River Mine coal processing plant in Berry, Alabama was in a bind. Due to new regulatory restrictions, available area, and construction scheduling, the plant was facing a possible interruption of ...

The problem of producing synthetic liquid fuels by alternative routes is addressed. Industrial processes known as Gas To Liquid (GTL), Coal To Liquid (CTL) and Biomass To Liquid (BTL) are considered: they use natural gas, coal and biomass as feedstocks, respectively. By means of process simulation, it is shown that the fuel ...