Energy From Palm Waste Articles & Analysis

198 articles found

In the face of mounting global waste disposal issues and environmental pollution, the need for innovative waste management solutions has never been greater. Among the most promising technologies is pyrolysis, a thermal decomposition process that not only helps manage waste but also contributes to energy recovery and resource conservation. Pyrolysis technology is quickly gaining traction in the ...

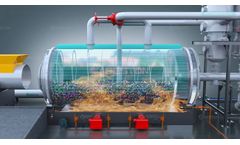

Pyrolysis technology has become a cornerstone in waste-to-energy and carbon-negative operations. Central to its efficiency and output quality is the pyrolysis reactor—where thermal decomposition of organic materials occurs in the absence of oxygen. Innovations in reactor design are reshaping the performance, scalability, and environmental footprint of modern pyrolysis plants. As demand ...

As global emphasis on energy efficiency intensifies, advancements in pyrolysis technology have shifted toward optimizing heat utilization and minimizing energy loss. Central to this evolution is the refinement of continuous pyrolysis plant design, which now integrates cutting-edge reactor engineering to enhance thermal performance, throughput, and system longevity. Evolution of Reactor ...

The demand for sustainable energy solutions and the urgent need for effective waste management have led to significant innovations in green technologies. One such solution that is gaining global attention is the biomass pyrolysis plant. These facilities, designed to convert organic materials into valuable byproducts like bio-oil, syngas, and biochar, are poised to play a crucial role in shaping ...

Anaerobic digestion can transform what was once considered a liability into a reliable energy source The imperative for sustainable practices in industrial operations has never been greater. Among the sectors facing increasing pressure to reduce environmental impact is the meat-processing industry. While the public conversation around this industry often centers on emissions and waste, it is ...

The Zichuan Solid Recovered Fuel (SRF) Plant Project is a mechanical pre-treatment facility for mixed municipal solid waste before incineration. It processes 1,000 tons of waste daily using two-stage shredding and mechanical separation to sort ferrous metals, non-combustibles (e.g., glass, stones, ash), and combustibles. In this project, JONO has implemented its advanced crushing technology to ...

Pyrolysis reactors play a crucial role in the conversion of waste materials into useful products, such as bio-oil, syngas, and char. Whether you are considering investing in a pyrolysis reactor for industrial purposes or as part of a waste-to-energy project, it's essential to understand the key components of these reactors and the factors to consider when purchasing one. This blog will provide an ...

Biochar production from waste coconut shells has garnered increasing attention as a sustainable business model that not only contributes to environmental conservation but also offers substantial economic benefits. As the demand for renewable resources and waste-to-energy technologies grows, the profitability of biochar production has become an important consideration for businesses and investors ...

The global ocean plastic pollution crisis has reached a critical point. Every year, millions of tons of plastic waste end up in the oceans, threatening marine life, disrupting ecosystems, and creating long-term environmental consequences. Traditional waste management and recycling methods have proven insufficient in addressing the sheer volume of plastic waste, particularly in coastal regions and ...

The growing interest in sustainability and resource efficiency has positioned biochar production as a key element in the circular economy. A biochar machine offers an efficient way to convert organic waste into high-value products that benefit both the environment and the economy. The versatility of biochar, combined with the increasing demand for eco-friendly solutions, makes investing in ...

Introduction Syngas, or synthesis gas, is a vital component in various industrial processes, serving as a fuel source and a raw material for chemical synthesis. It is primarily used in power generation, chemical production, and fuel manufacturing. Accurate measurement of syngas is critical to ensuring efficiency, safety, and compliance with industry standards. This article explores the ...

Introduction Biogas, a renewable energy source produced from organic waste, plays a critical role in reducing greenhouse gas emissions and providing sustainable energy. One of its primary components, methane, is essential for energy production, making its accurate measurement vital. This guide explores how to measure methane in biogas, best practices, and the advantages of Cambridge ...

When exploring renewable energy solutions and waste-to-energy technologies, two methods often emerge in discussions: biomass gasification and pyrolysis. While both processes involve the conversion of organic materials into valuable energy, they operate on different principles and produce distinct outcomes. Understanding the differences between biomass gasification and pyrolysis is crucial for ...

The Emerald Energy from Waste Facility (Emerald Energy) is located in the suburban area of Toronto, Ontario, in the City of Brampton. Recently purchased from Algonquin Power Energy Fund by Upak Disposals, Emerald Energy is a privately-held waste collection and recycling company with a 45-year track record of success. Gordon Hoskinson invented the core pyrolytic gasification technology, which has ...

The HWTEF was developed for Harford County by the Northeast Maryland Waste Disposal Authority (the Authority) under its revenue bond financing authority. The Authority owned the facility on behalf of Harford County and operated by Energy Recovery Operations, Inc. (EROI). It was decommissioned last year after more than 20 years of successful operations due to the U.S. Army not renewing the land ...

Since a successful start in January 2018, the first commercial Cryo Pur unit has been continuously producing bio-LNG at the Greenville Energy site in Northern Ireland. This confirms the success of the first plant in the world producing liquid biomethane on a farm. With a capacity of 3 tons per day of LNG (300 Nm3/h of raw biogas), the plant provides local industries with storable renewable ...

ByCryo Pur

Critical considerations for anaerobic digestion projects In the field of industrial wastewater treatment, anaerobic digestion is a powerful process that transforms waste into valuable by-products. Most notably, it produces renewable energy in the form of biogas, which can be used to fuel operations, cogenerate electricity, or even be sold. Another valuable by-product of the process is digestate, ...

Pyrolysis is a thermal decomposition process that breaks down organic materials, such as plastic, rubber, and biomass, in the absence of oxygen. This process has gained significant attention for its potential in waste management and resource recovery, offering an effective way to convert waste into valuable products like fuel, gas, and biochar. A key question that often arises is whether ...

The thermal efficiency of a pyrolysis reactor is a critical factor in determining the overall performance, energy consumption, and economic feasibility of the pyrolysis process. Pyrolysis, a thermochemical decomposition process, is used to convert organic materials such as plastics, rubber, and biomass into valuable products like oil, gas, and charcoal. The efficiency with which the reactor ...

Situation Most people know HVC as a waste-to-energy plant or waste company. However, the fact that HVC is also active in generating renewable energy from green gas, solar parks and geothermal energy is much less known. In the Westland region, the soil is extremely suitable for utilising geothermal energy, or geothermal heat. HVC is now working on its third geothermal plant in this region, ...