Plasma Processing Articles & Analysis

14 articles found

Basically everyone is familiar with the three most famous states of matter: solid, liquid, and gas. However plasma the fourth state of matter is unfamiliar to most people. When asked what plasma is most people think about the plasma in blood which is the liquid that transports nutrients throughout the human body. Less people will think about the plasma that is generated in the northern- and ...

In materials science, precision in thin film deposition processes like Plasma Enhanced Atomic Layer Deposition (PEALD) is paramount. The ability to control film thickness and composition with high accuracy depends significantly on understanding and controlling the plasma used in the deposition process. Here, the Hiden EQP Series ...

Low-pressure plasma applications are pivotal in the advancement of materials science and surface engineering. ...

The semiconductor fabrication industry, which is vital to the modern digital era, hinges significantly on the precision and purity of gasses used in its manufacturing processes. Ultra high purity gas mixing plays a pivotal role in ensuring the quality and performance of semiconductors. This article delves into the intricacies of ultra high purity gas mixing. It explores its importance, ...

As the world works to reduce greenhouse gas emissions, global adoption of electric vehicles (EVs) is driving an increased demand for high-power, energy-efficient compound semiconductors, such as silicon carbide (SiC)-based components, throughout the entire EV assembly process. Renewable energy technology is now at the forefront of climate-forward research, with accelerating EV sales playing a ...

Abstract Detailed knowledge of correlations between direct current (DC) cathodic arc deposition process parameters, plasma properties, and the microstructure of deposited coatings are essential for a comprehensive understanding of the DC cathodic arc deposition process. ...

The active layer was fabricated using double alignment technology (electron–beam lithography and NIL), and the fin trench was filled perfectly by using a high–density plasma chemical vapour deposition process. Advanced plasma and wet etching processes were employed to obtain the fin height. The fabricated FinFET could provide a ...

We observed how the thermoelectric properties of the material improved with the annealing temperature, being a spark plasma sintering process needed to maintain the material nanostructuration while maximising its electrical properties. ...

Pilot setups in which the above processes occur in the electron–beam plasma (EBP) and combined plasma (CP) are described. ...

ABSTRACT: Electric arc furnace (EAF) dusts, have been successfully treated in plasma-fired carbothermic reduction furnaces to recover metal values. Although the technology is equally applicable across the range from plain carbon to stainless steels, historically, it is the latter that has been the more commercially successful. Because the plasma heat source is ...

We create polymeric microfludics/microsystems using plasma processing as well as 'smart' polymer surfaces with controlled wetting and optical properties. First, fabrication of polymeric micro-nanosystems and microfluidics using standard photolithography followed by plasma etching is proposed as an alternative method for polymer microfabrication. ...

Thermonuclear plasmas are complex and highly nonlinear physical objects and, therefore, are the most advanced present-day devices for the study of magnetic confinement fusion. ...

This paper presents the major by-products derived from Nonthermal Plasma (NTP) chemical processing of different types of Volatile Organic Compounds (VOCs), mechanisms for their formation, effects of reactor types and additives such as water and gaseous oxygen on by-product distribution, and safe operations of NTP reactors for the removal of VOCs.Keywords: VOC ...

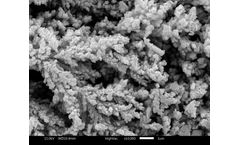

In this study we continue our research efforts pertaining a novel, simple, generic and fast technique to fabricate stable super-hydrophobic, yet transparent surfaces by means of high-density plasma etching and deposition. A High Density Plasma reactor is used to treat two different kind of polymers; an organic one (PMMA) and a hybrid one (PDMS). ...