Pyrolysis Machines That Can Process Articles & Analysis: Older

293 articles found

Through the integration of a charcoal making machine, this process offers a sustainable alternative to traditional practices, emphasizing resource efficiency and ecological preservation. ...

Pyrolysis is a thermal decomposition process that breaks down organic materials, such as plastic, rubber, and biomass, in the absence of oxygen. This process has gained significant attention for its potential in waste management and resource recovery, offering an effective way to convert waste into valuable products like fuel, gas, and biochar. A key question that often arises is whether ...

Collect the fuel oil from the condenser attached to the pyrolysis reactor. This fuel oil can be further refined and processed if necessary. ...

The operation of biochar production equipment involves a series of meticulously controlled processes that transform organic biomass into a valuable byproduct. Biochar, a stable form of carbon, is created through the thermochemical conversion of organic materials in the absence of oxygen, commonly referred to as pyrolysis. This process not only reduces waste but also yields a product that has ...

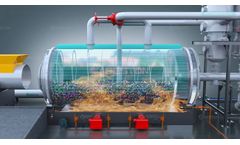

Setting up a continuous pyrolysis machine project involves a range of equipment and systems that work together to efficiently process waste materials (such as tires, plastics, rubber, medical waste, construction waste, e-waste, etc.) into useful by-products like fuel oil, carbon black, and syn-gas. ...

The thermal efficiency of a pyrolysis reactor is a critical factor in determining the overall performance, energy consumption, and economic feasibility of the pyrolysis process. Pyrolysis, a thermochemical decomposition process, is used to convert organic materials such as plastics, rubber, and biomass into valuable products like oil, gas, and charcoal. The efficiency with which the reactor ...

During pyrolysis, plastic waste is broken down into simpler compounds, resulting in a mixture of gases, liquid fuel, and solid residue. ...

A continuous pyrolysis plant is designed to streamline the conversion of waste materials, such as plastics and tires, into valuable resources like fuel oil, carbon black, and syngas. Understanding its operating cycle time is essential for businesses and operators to achieve efficiency, maximize output, and make informed decisions about processing volumes, energy usage, and maintenance scheduling. ...

The biomass fraction of pyrolysis refers to the portion of biomass material that undergoes thermal decomposition in the pyrolysis process to produce valuable products such as biochar, bio-oil, and syngas. This fraction is significant in determining the efficiency and output of a pyrolysis system. Key Aspects of the Biomass Fraction in Pyrolysis 1. Composition: Biomass is primarily composed of ...

Sealing is a crucial factor in the overall performance and efficiency of a pyrolysis reactor. The technology behind pyrolysis revolves around the thermal decomposition of materials in the absence of oxygen. Any failure in sealing leads to oxygen infiltration, disrupting the pyrolysis process. This not only affects the quality of the end products but also poses serious safety risks. Understanding ...

Through innovative carbonization machine, rice husks can be transformed into biochar, bringing new vitality to agriculture, energy, environmental protection and other fields. ...

The mini pyrolysis plant represents a significant opportunity for investors looking to enter the waste-to-energy sector. By converting waste materials such as plastics, tires, and biomass into valuable by-products, mini pyrolysis plants offer a sustainable solution to waste management while generating potential revenue streams. Understanding the investment scenario for a mini pyrolysis plant ...

Condensation: The gaseous products of pyrolysis are cooled and condensed into liquid fuels. This phase also involves the collection of non-condensable gases, which can be used as energy for the process. ...

Continuous pyrolysis is a complex process that requires specialized equipment. The journey from concept to operational equipment involves several stages: Design and Engineering: This phase includes detailed equipment design, material selection, process simulation, and safety considerations. Manufacturing: The actual construction of the equipment, involving fabrication, assembly, and testing. ...

In January 2014 BTG Bioliquids / Empyro BV started construction of its pyrolysis oil production facility in Hengelo, the Netherlands. The Empyro plant converts 5 tons per hour of wood residues into pyrolysis oil, process steam and electricity. Start-up of the installation commenced in early 2015 and production has gradually increased since. Nameplate capacity was reached in 2017 and since then ...

Pyrolysis is a transformative technology that can effectively process a wide range of waste materials, converting them into valuable products like fuel oil, carbon black, and gas. This article outlines the types of raw materials suitable for pyrolysis and describes the general process flow of a waste ...

Beston Group has developed a cutting-edge catalytic pyrolysis technology that significantly enhances the efficiency and environmental friendliness of the process. By introducing catalysts into the reaction chamber, Beston's technology achieves several key benefits: Improved Oil Quality: Catalysts facilitate the breakdown of complex plastic molecules, resulting in higher-quality fuel oil with ...

A pyrolysis reactor is a sophisticated piece of equipment used to thermally decompose organic materials in an oxygen-free environment, yielding valuable products such as bio-oil, syngas, and biochar. Proper maintenance of a pyrolysis reactor is critical to ensure its efficient operation, longevity, and safety. This article provides a detailed guide on how to properly maintain a pyrolysis reactor, ...

Understanding Biomass Pyrolysis Biomass pyrolysis is a thermochemical decomposition process that occurs in the absence of oxygen. ...

Look for manufacturers who: Invest heavily in R&D to enhance machine performance and efficiency. Employ cutting-edge technologies in their machines to optimize the pyrolysis process. ...