- Home

- Companies

- Rise Technology srl

- Products

Rise Technology srl products

PV Equipment - Solar Cell Tabber Stringer

Twin - Solar Cell Tabber Stringer

RISE TECHNOLOGY SRL enlarges its Tabber&Stringer range with TWIN introduction. Realized to satisfy the demands for rising production in increasingly contained spaces, in order to obtain an high line efficiency. With TWIN, plants with high production (up to 7.200 cells/hour) can be realized with a reduction of maintenance costs close to 40%.

Spirit - Solar Cell Tabber Stringer

SPIRIT is the best solution to achieve high performance and quality thanks to infrared soldering technology and heating areas that limit the cell breakage during the process. The Tabber Stringer allows to store in its memory various production cycles, through a PLC. The cells are automatically picked from two loading baskets and positioned correctly thanks to the mechanical or optical centring system; then they are soldered with infrared lamps. The result is the creation of strings composed by up to 12 cells, with size from 125x125 mm to 156x156 mm. The machine can be in “stand alone” configuration or it can be insert in the Lay out LO072AR, if the SPIRIT is inserted in a complete production line. Touch-screen panel that allows to customize the welding cycle and a lot of other working parameters in a very easy way. Connection by modem to guarantee a technical support in real time worldwide.

Preface - Solar Cell Tabber Stringers

PREFACE is the best solution to achieve high performance and quality thanks to infrared soldering technology and heating areas that limit the cell breakage during the process. The Tabber Stringer allows to store in its memory various production cycles, through a PLC. The cells are automatically picked from two loading baskets and positioned correctly thanks to the mechanical centring system; then they are soldered with infrared lamps. The result is the creation of strings composed by up to 12 cells, with size from 125x125 mm to 156x156 mm. The machine can be in “stand alone” configuration or it can be insert in the Lay out LO072AR, if the PREFACE is inserted in a complete production line. Touch-screen panel that allows to customize the welding cycle and a lot of other working parameters in a very easy way. Connection by modem to guarantee a technical support in real time worldwide.

PV Equipment - Solar Cell Layout

Model LO072AR - Fully Automatic Solar Cell Layout Systems

LO072AR is a fully automatic system, thanks to its Kuka Robot, it permits to automate the production cycle, through the combination with up to two tabber&stringers and with one or more laminators. The Lay out picks up the soldered strings from the tabber&stringer and deposits them on the glass module; after EVA and Tedlar film deposit and strings interconnection welding, this machine transports and introduces the sandwich into the laminator. As the lamination process is over as the LO072AR unloads the module on a special conveyor. Connection by modem to guarantee a technical support in real time worldwide. Touch-screen panel that allows to customize the different cycle and a lot of other working parameters in a very easy way.

Model LO072A - Fully Automatic Solar Cell Layout System

LO072A is a fully automatic system, it permits to automate the production cycle, through the combination with up to two tabber&stringers and with one or more laminators. The Lay out picks up the soldered strings from the tabber&stringer and deposits them on the glass module; after EVA and Tedlar film deposit and strings interconnection welding, this machine transports and introduces the sandwich into the solar panel laminator. As the lamination process is over as the LO072A unloads the module on a special conveyor. Connection by modem to guarantee a technical support in real time worldwide. Touch-screen panel that allows to customize the different cycle and a lot of other working parameters in a very easy way.

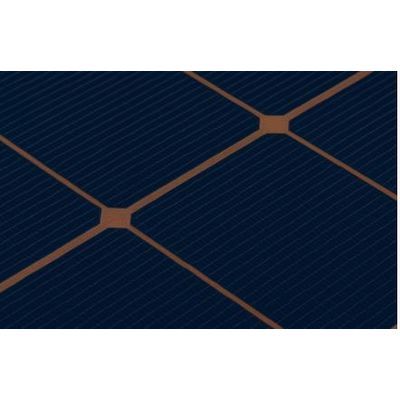

Rise - Photovoltaic System

RiseTech revolutionizes PV manufacturing with its innovative localized electrochemical deposition technology. By precisely electrodepositing copper—replacing costly silver—we significantly reduce production costs, increase panel efficiency, and enhance sustainability. Our patented technology ensures accuracy and zero material waste, enabling more affordable and environmentally friendly solar energy solutions.

Rise - Power Systems

RiseTech transforms power electronics manufacturing with its advanced localized electrochemical deposition technology. By precisely depositing silver only where needed, we eliminate unnecessary coating or complex lithography steps. This approach significantly reduces material use and streamlines production, resulting in substantial cost savings and enhanced device performance.

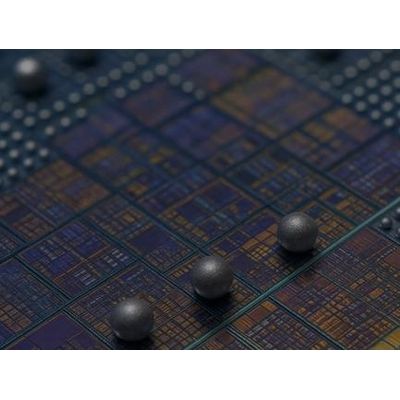

Rise - Semiconductor

RiseTech advances semiconductor manufacturing through low-temperature soldering electrodeposition. Our unique capability to rapidly electrodeposit multi-material alloys-such as SAC solder-allows precise layering of different metals, a feat impossible with traditional methods. This approach unlocks new alloy possibilities, boosting efficiency and performance in semiconductor packaging.

Preparation Solar Cell Raw Materials

SUNCHECK - Model 8 - Automatically Solar Cells Sorter

SUNCHECK8 sorts automatically solar cells according to their electrical data, measured by flash testing system. The sorter basically consists of the cell loading unit connected to the measurement system and finally to sorting bins. The testing system, controlled by pc, collects all relevant data according to IEC 1215, EN 61215, UL 1703 allowing different sorting criteria. It is designed to guarantee high performance and flexibility with maximum care of cell handling. In addition every sorting basket is easily movable to tabber&stringer for a quick loading.

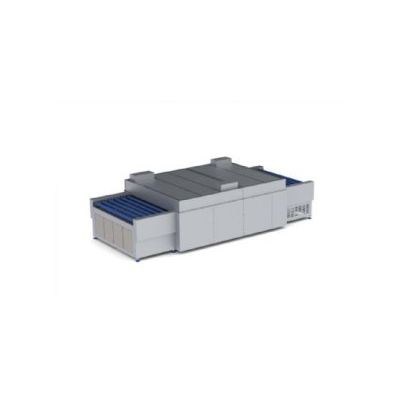

Model GW200A - Solar Cell Glass Washer

GW200A is made of sturdy, painted steel tubes while the inside parts in contact with water and the drying area are completely made of stainless steel. The opening of the upper structure is carried out by four worm screws with four angle transmission powered by a gear motor. Every washing unit has a water collecting tank that is let in again by means of a pump into the nozzle-carrying tubes after being filtered.