digester-gas Downloads

34 downloads found

The Shand & Jurs Biogas Model 97180 Foam Separator is designed for use in piping systems to remove foam caused by agitation from the digester discharge gas. The foam must be dispersed and collected in order to protect downstream equipment from corrosion or clogging. The Foam Separator is typically installed in the digester ...

Landfill gas is a by-product of the solid waste decomposition of organic matter deposited in landfills.Digester gas is a by-product of the digestion of sewage sludge.The effluent gas produced in these processes consists mostly of methane and carbon dioxide together with water vapor and minor quantities or organic compounds.PSB Landfill / Digester Gas Dryers remove water vapor and impurities so ...

Methane Biogas is increasingly being used for plant utilities and in some cases also to generate power. Anaerobic digestion is the process generating methane biogas at municipal sewage treatment facilities, landfills, agricultural and even the food and beverage industries. It is very important to routinely perform maintenance on each piece of digester ...

Designed to meet Global Renewable Energy and Carbon Credit digester project requirements, the BIOGAS5000 is the ideal eld instrument for anaerobic digester gas analysis. Easy-to-use and portable, the BIOGAS5000 measures gas composition and ow with repeatable accuracy on farms, food processing plants and waste water treatment ...

The highest return on investment of any digester available. The Dystor system uses a dome-shaped, engineered membrane system to store biogas, and prevent odors. The Dystor system’s outer membrane remains inflated in a fixed position. The inner membrane moves freely as it stores or releases biogas generated from the anaerobic digestion process. This system can hold up to six times as much ...

ST51 Mass Flow Meter For Biogas, Digester Gas, Methane and Natural Gas? Wastewater Treatment Plant Digester Systems? Biogas Production and Recovery— Anaerobic Digester Processes— On-Farm Systems— Fermentation Systems? Landfill Gas Recovery Systems? ...

A gas dome is a component of the digestion tower positioned above the digested sludge, with the purpose of allowing the digested gas to escape in a controlled ...

It is also important to monitor the gas coming out of the digester to ensure the digester health levels are optimally maintained and that greenhouse gas emissions can be accurately reported.A sensor used to monitor the biogas output can provide an indicator to efficiency of the digester. Gas produ ...

Anaërobe Vergisting & Groen Gas • Biogas• Groen Gas• Proces- optimalisatie• OnderzoekAnaërobe Vergisting & Groen Gas Kwaliteit en kwantiteit van biogasDe kwantiteit en de kwaliteit van het biogas wordt in belangrijke mate bepaald door het ontwerp én de bedrijfsvoering. ...

The gas dome or gas cover is used first and foremost as the basis for various attachments for digesters, i.e., foam traps, gas extraction units, safety devices, mixers, measurement units etc., and secondly as an access point into the digester. For both applications the gas dome should be ...

The Shand & Jurs Biogas 97126 Gas Purifier removes unwanted components, such as hydrogen sulfide (H2S), from low pressure gas streams. Typical applications include anaerobic digester gas trains, municipal landfills, anaerobic lagoons, pulp and paper digesters, food and beverage making, and other fermentation ...

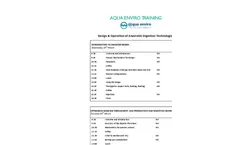

Design & Operation of Anaerobic Digestion Technologies INTRODUCTION TO DIGESTER DESIGN Wednesday 23 rd March 9.30 Welcome and Introduction NH 9.45 Process biochemistry for design NH 10.30 Feedstock MS 11.15 Coffee 11.30 Determination of design retention times and OLR NH 12.15 Reactor configurations MS 13.00 ...

The 97311 was specifically designed to completely combust gas in digester and landfill systems. With a minimum destruction efficiency of 99%, the 97311 provides low NOX and CO emissions levels. This burner is ideal for environments that have strict emission requirements and regulations (such as the EPA) and keeps emissions within the allowable limit. ...

Design & Operation of Anaerobic Digestion Technologies INTRODUCTION TO DIGESTER DESIGN Wednesday 23rd March 9.30 Welcome and Introduction NH 9.45 Process biochemistry for design NH 10.30 Feedstock MS 11.15 Coffee 11.30 Determination of design retention times and OLR NH 12.15 Reactor configurations MS 13.00 Lunch 14.00 Using the biogas ...

The compact design LCV combustor was originally designed to serve PSA digester gas upgrading systems for municipal biogas or sewags sludge fermenters. It is able to burn up to 100 Nm³/h (NCMH) of LCV gas. For methane concentrations in the LCV gas of 7 Vol% it can burn the gas without auxiliary fuel. Up to 15 Vol% is possible. The detailed design is adopted by varying the size of the ...