Refine by

Desulfurization Articles & Analysis

68 news found

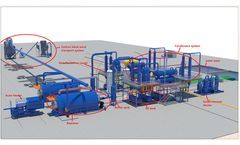

Environmental Protection Equipment Dust Collector: Captures particulate matter from flue gas to meet emission standards. Desulfurization Tower: Removes sulfur compounds to prevent acid rain and corrosion. ...

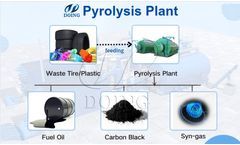

Without oxygen, the harmful gases and pollutants that are usually generated during combustion do not form. (2) During the pyrolysis process, the gas produced by heating undergoes desulfurization and dust removal through the desulfurization and dust removal system. ...

These configurations ensure that the waste treatment process has minimal impact on the environment Here. are some key features: ① Exhaust Gas Treatment Devices: Low Emission Design Equipped with advanced exhaust gas purification devices such as desulfurization towers and pulse dust collectors, DOING’s environmentally friendly pyrolysis machines effectively remove harmful ...

Our machine is equipped with advanced Exhaust gas purification system and emission control systems like desulfurization tower and dust removal devices that effectively reduce the release of harmful gases and particulate matter during the pyrolysis process. ...

Unconventional Gas Solutions (UGS), the specialist in gas upgrading systems, announces the successful commissioning of two innovative biogas upgrading plants in the US states of Michigan and Wisconsin. The two plants, which together feed 800 Nm3/h of biomethane into the local gas grid, are the first UGS systems of their kind. The two projects exemplify the company’s commitment to developing ...

“Greenlane is also unique in the industry being the only biogas upgrading company offering and deploying systems utilizing the three main upgrading technologies: waterwash, pressure swing adsorption, and membrane separation, independently and in combination, plus proprietary biogas desulfurization technology. It is this deep level of understanding, unbiased perspective on ...

Greenlane is the only biogas upgrading company offering and actively deploying multiple core technologies: water wash, pressure swing adsorption (PSA), membrane separation, plus proprietary desulfurization solutions. Greenlane solutions are built around standard product platforms. ...

Exposure to these pollutants can harm people and ecosystems by contaminating drinking water sources, recreational waters, and aquatic life.EPA’s final rule establishes technology-based discharge standards—known as Effluent Limitation Guidelines (ELGs)—that will apply to four types of wastewater:Flue gas desulfurization wastewaterBottom ash transport waterCombustion residual ...

For example, the tail-gas cleaning system and desulfurization tower can realize fully purification of the exhaust gas to meet the emission standards in many countries; In addition to manufacturing pyrolysis plants, DOING Group also provides comprehensive services, including installation, training, and after-sales support. ...

Emission Control System: To ensure environmental compliance, continuous pyrolysis machines are equipped with emission control systems such as flue gas purification and desulfurization system to reduce pollutants released into the atmosphere. 6. ...

Hydrogen sulfide is a pungent gas, which is very unpleasant, so we specially designed an exhaust gas purification system to remove hydrogen sulfide. The flue gas desulfurization tower It’s a higher configuration flue gas purification system, which can satisfy customers who have higher requirements for environmental protection. 5) The vacuum system It’s a safety ...

Power Generation In power generation facilities, such as coal-fired power plants and thermal power stations, high alumina bricks are utilised in boilers, furnaces, and flue gas desulfurization systems. The bricks' ability to withstand high temperatures, thermal shock, and chemical corrosion renders them suitable for lining critical equipment. ...

DOING pyrolysis plant is equipped with some environmental protection systems, such as the tail-gas cleaning system and desulfurization tower, which can purify the exhaust gas to meet the emission standards in various countries. 4. ...

To extract the crystals, a small amount of the desulfurizing bicarbonate soda solution is transferred from the oxidation tank to a small decanter centrifuge. ...

Smoke Pollution Prevention and Control For flue gas pollution, it is equipped with a desulfurization and dust removal tower, which can burn the SO2 component contained in the flue gas during the pyrolysis process. ...

Like in other countries the UK has an incentive to promote the production of renewable green gas, currently we know this incentive as the RHI (Renewable Heat Incentive). This is soon to take a different name under new reforms coming March 2021. The Green Gas Support Scheme (GGSS) is an incentive to increase the proportion of green gas in the National Gas grid, like the RHI. It supports the ...

DMT International’s Global Sales & Marketing Director, Francois Huberts, explains 2020 has been a success for the biogas upgrading technology supplier despite the coronavirus (COVID-19) pandemic. “It’s been a challenge,” stated Huberts, “but DMT has continued its commissioning activities and technical support to projects around the globe. The main offices in ...

Biogas purification is an indispensable part of the biogas production process, because H2S in biogas is a flammable colorless gas, and its aqueous solution is called hydrosulfuric acid, which is corrosive. Biogas desulfurization purification equipment is mainly used to remove H2S in biogas, prevent its corrosion to biogas combustion equipment and pipelines, and extend the service ...

DMT, a leading technology supplier in biogas upgrading and gas desulfurization, announces Seabreeze Farm, a third-generation dairy farm owned by the Keulen family, will update their Renewable Natural Gas (RNG) equipment using DMT’s patented three-stage membrane separation system. ...

Clarke Energy supplied and installed our first biogas upgrading plant at a waste water/sewage treatment plant (STEP) in Perpignan, France. The membrane treatment technology used upgrades biogas produced from sewage to biomethane and this is the first in project in the French region of Occitania and the Mediterranean Arc. The renewable gas that is produced is injected into the local gas ...