Pyrolysis Machines That Can Process Articles & Analysis: Older

93 news found

When considering the operational modes, pyrolysis plants can primarily be categorized into three distinct types: batch, semi-continuous, and fully continuous. Each type has its unique characteristics and applications, catering to a variety of industrial needs and waste management scenarios. They are all available from China top pyrolysis plant manufacturer Henan Doing Company. DOING Brand ...

Yes, DOING pyrolysis machines can be customized to meet the specific requirements and needs of clients. ...

Pyrolysis oil, derived from the thermal decomposition of solid waste like waste tires, plastic scrap, oil sludge or other organic materials, can find applications in the metal smelting industry. Here’s how: (1)Fuel Source: Pyrolysis oil can serve as a supplementary or alternative fuel in metal smelting furnaces. Its high energy content and combustion properties make it suitable for ...

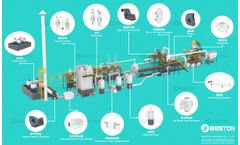

The plastic to fuel oil pyrolysis process involves breaking down plastic waste into smaller molecules using high temperatures in the absence of oxygen. This process typically results in the production of valuable fuel products like pyrolysis oil, gas, and carbon black. Here is a general overview of how DOING pyrolysis plant's plastic pyrolysis process works: (1)Feedstock Preparation: Plastic ...

The technology of continuous pyrolysis machine is a method used to convert various types of waste materials, such as rubber tire powder, waste plastic pieces, etc. into valuable products like fuel oil, gas, and carbon black through a continuous and controlled thermal decomposition process called continuous pyrolysis technology. ...

Pyrolysis is a thermal decomposition process that involves heating organic materials in the absence of oxygen. pyrolysis machine is used for various purposes and has several applications, including: 1. ...

However, with pyrolysis oil distillation machine, we can improve tire pyrolysis oil quality by distillation, cooling, decolorization and flavor removal for wider uses and better benefits. ...

When the raw material is not a problem for you, you can use pyrolysis machine to recycle plastic into fuel oil. Then we will introduce the detailed process of recycling plastic into fuel oil with pyrolysis machine: 1. ...

DOING company has manufactured pyrolysis machines for over 13 years, and we can provide high quality pyrolysis machines with different designs and different configurations for our customers to meet their different demands. ...

The Fraunhofer Institute in a first data analysis of the entire process chain confirms Pyrum’s pyrolysis process saves significantly more CO2 compared to conventional recycling methods Pyrum Innovations AG has once again proven the sustainability of its business model. A scientific study by the Fraunhofer Institute recently published in the renowned journal “Resources, Conservation ...

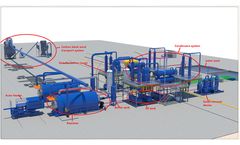

A fully continuous waste tire to fuel oil pyrolysis processing line is a system designed for the recycling of waste tires through a process called pyrolysis. In the case of tire pyrolysis, waste tires are heated to a high temperature in a reactor, resulting in the breakdown of the tire materials into various by-products, including fuel oil, carbon black, and combustible gas. A fully continuous ...

Their product portfolio includes: Waste Tyre Pyrolysis Plant: recycle waste rubber tyres to fuel oil, carbon black, steel wire and combustible gas; Waste Plastic Pyrolysis Plant: recycle waste plastics(such as PP/PE/PS/ABS plastics) to fuel oil, carbon black and combustible gas; Waste Oil Sludge Pyrolysis Plant: recycle oil sludge to fuel oil, ...

Their product portfolio includes: Waste Tyre Pyrolysis Plant: recycle waste rubber tyres to fuel oil, carbon black, steel wire and combustible gas; Waste Plastic Pyrolysis Plant: recycle waste plastics(such as PP/PE/PS/ABS plastics) to fuel oil, carbon black and combustible gas; Waste Oil Sludge Pyrolysis Plant: recycle oil sludge to fuel oil, ...

Pyrolysis Process High Temperature The pyrolysis process in charcoal making machines involves subjecting coconut shells to high temperatures (typically 400-600°C) in the absence of oxygen. ...

Introduction The Importance of Reliable Pyrolysis Plant Manufacturers Selecting a trustworthy pyrolysis plant manufacturer is a critical decision for businesses and entrepreneurs venturing into waste-to-energy projects. The reliability and integrity of the manufacturer significantly impact the success and longevity of such projects. The Significance of Due Diligence in the Selection Process Due ...

While various types of plastics are commonly subjected to pyrolysis, PET (polyethylene terephthalate) plastic stands as an exception, PET cannot be used for pyrolysis, and this article aims to explore the reasons why PET is not suitable for pyrolysis and the environmental considerations associated with its use in the pyrolysis ...

The world of pyrolysis has witnessed a flurry of new developments in recent years, ushering in a wave of innovative pyrolysis plant designs. Businesses are increasingly recognizing the immense potential of pyrolysis technology for their operations. One particularly intriguing advancement is the fully continuous pyrolysis plant reactor design. One of the most striking features of the fully ...

This article delves into the technology, benefits, types, and considerations of biochar production equipment. Biochar Production Process Pyrolysis: The Heart of Biochar Production At the core of biochar production equipment lies the pyrolysis process. ...

The proliferation of waste tires is a global environmental challenge, necessitating innovative solutions. Pyrolysis plants have emerged as a promising technology for converting discarded tires into valuable pyrolysis oil. In this article, we explore the technical intricacies and environmental benefits of this sustainable process.Pyrolysis Process: A Technical OverviewPyrolysis as a Thermochemical ...

One such innovation that has gained significant attention is the Coconut Shell Charcoal Making Machine. This article delves into the profound impact of these machines on agriculture, shedding light on their production process, utilization in farming, environmental benefits, economic advantages for farmers, and the challenges and prospects in this ...