P.Energy - Model FURBA Series - Combined Tabber-Stringer Machines

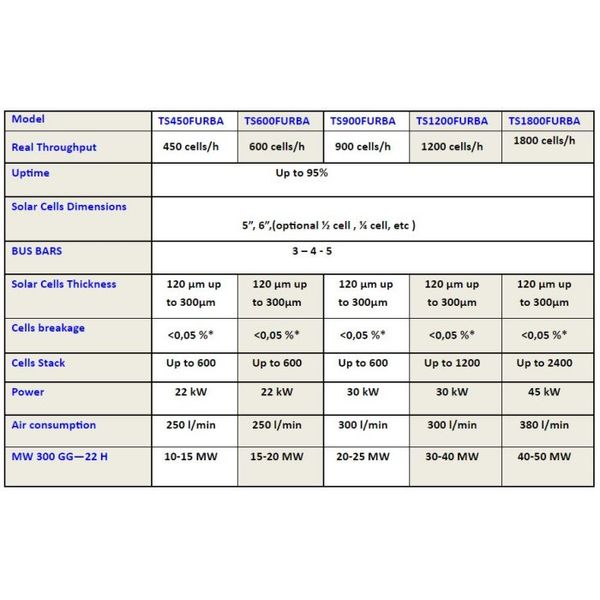

The new Combined Tabber-Stringer machines of the FURBA series are the result of 15 years of constant development in the field of photovoltaic technology. The new CTS FURBA series is composed by: TS450FURBA, TS600FURBA, TS900FURBA, TS1200FURBA, TS1800FURBA.

Stringers “FURBA” SERIES is a series of full automatic tabbing/stringing machines. It represents the best solution for automated assembly lines with high performance, reliability and quality needs.

The single or double track unloading belts allow to install the machines in a reduced space and to work in connection with the layout station LO072AR.

All the machines of the series have a new robust and compact design that permits an easy installation and setup and a quick ramp up of the production. All components are easily reachable to optimize uptime and maintenance.

The iron welded structure has been designed for an easy access, providing the operator with a wide working space. A full set of instruments keeps constantly informed about the working state of the machine.

PV cells stacks are sorted in special baskets and placed on the loading belts of the machine up to five at time. Once a basket of cells reaches the loading position, the vacuum handling system takes the cells one by one and places them on the checking system, where a camera detect the broken ones. The cells which satisfy this quality test are aligned by another camera and placed on the soldering belt.

The soldering belt is heated in order to prevent and reduce the thermal stress on the strings. Cells are held down by a vacuum system.

The motorized ribbon unwinding system and the new stretching system permit a precise positioning of the ribbon on two or three bus bars avoiding bowing and misalignment.

The infrared soldering system focus the light beams on the ribbon lines for a constant welding process, allowing to string also thin cells down to 160µm and using lead and lead free ribbon.

All STRINGERS of the “FURBA” SERIES are easy to control and use, and their setup is quick and affordable also for new operators. A simple and wide 15” touch screen with finger print access permits to control and setup all the process parameters.

PLC Siemens Simatic Panel HMI PC permits the fully control of the machine processes trough an easy-to-use 15” Touch Panel

- The integrated pc permits the storage and the customization of the process

- Real time assistance is granted by Ethernet port RJ45, used also for SCADA system (optional P.ENERGY SCADA).

P.ENERGY – PHOTOTRADE CTS “FURBA” Series is provided with a high speed infrared soldering system.

- 3,4 or 5 IR lamps focus the light beams on the ribbon lines for a constant welding process (not spots welding process).

- 5 preheated zones on the soldering belt with settable temperature prevent the thermal stress on the cells before the soldering process.

- All the Vacuum plates are treated with DURAFLON®. DURAFLON® is a special treatment for aluminum surfaces that gives maximum protection from corrosion, from wearing and improves the hardness and the smoothness.

- The soldering belt is made of woven glass fiber covered by a double layer of Teflon.

The combination of optical centering system, visual quality system, precise movements and high quality of mechanical components allows to use also extremely thin cells.

P.ENERGY – PHOTOTRADE CTS “FURBA” Series use a force controlled unrolling ribbon system. The constant force applied to the ribbon ensures its correct stretching and alignment onto the cell and prevents it to be looped on the spool.

This increases the power of the strings, because of the larger contact area between ribbon and bus bars.

|

Dimensions 450FURBA, 600FURBA, 900FURBA:

|

|

Dimensions TS 1200FURBA , TS1800FURBA :

|