GE - Model 6F -Gas Turbine

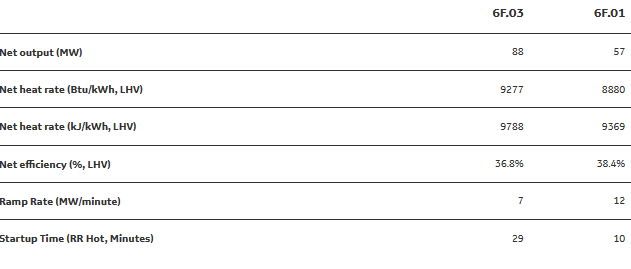

GE’s 6F gas turbines offer the superior performance, reliability, and flexibility typically associated with larger power plants. The 6F models, including the 6F.01 and the 6F.03 gas turbines, pack a lot of power into a small package, offering durability and flexibility for harsh, remote, or floating power environments. Whether it be for 50 or 60 Hz, the 6F gas turbines maintain best-in-class output and exhaust energy for combined cycle and CHP performance. The 6F.01 and 6F.03 offer segment-leading approximately 32,000-hour combustion and hot gas path inspection intervals.

6F gas turbine features and benefits

With its combination of high efficiency and low emissions, the 6F gas turbine is a reliable, environmentally-friendly choice.

The 6F.01 gas turbine is a compact yet powerful driver of combined-cycle and cogeneration plants, with a versatile configuration offered in either cold end drive for enhanced output, or hot end drive for repowering existing 6B power plants, while the 6F.03 gas turbine’s enhanced flexibility makes it an excellent choice for a variety of applications, as well as a variety of environments.

The 6F.01 gas turbine has over 160,000 hours and 1,700 starts of fleet operating experience over the past four years, while the 6F.03 gas turbine has over 140 units currently in use worldwide.

Capable of operating on a wide range of fuels like natural gas, distillate, and synthetic, the 6F.03 can achieve turndown to 52% load using Dry Low NOx (DLN) 2.6 combustion. This DLN 2.6 combustion system enables lower emissions—less than 15 ppm NOx or 9 ppm CO—and 32,000-hour combustion inspection intervals.

The 6F.01’s 12-stage compressor provides 3D aerodynamics for high efficiency, removable blades for high reliability, cold end drive with axial exhaust for high efficiency, and 64,000-hour major inspection intervals. It has field-replaceable compressor airfoils and utilizes proven hot gas path and combustion materials featured on 7F.05, 9F.05 and H-class turbines, that can support higher temperatures. The 6F.01’s 600˚C exhaust temperature allows up to 140 bar high pressure steam, making it ideal for combined heat & power applications.