- Home

- Equipment

- new zealand

- process heating

Refine by

Process Heating Equipment Supplied In New Zealand

9 equipment items found

Manufactured by:Windsor Engineering based inPorirua, NEW ZEALAND

Crossle Coils Steam Coils provide a robust heat exchanger that is compact yet supplies superb thermal performance. Coils are available for Low Pressure Flash Steam applications or High Pressure Space Heating or Process Heating Applications. Steam Coils can be designed to specification, manufactured to customer drawings, or ...

Manufactured by:Windsor Engineering based inPorirua, NEW ZEALAND

Crossle Coils manufacture a wide range of Hot Water or Thermal Fluid Heat Recovery Coils. A Heat Recovery Coil is principally designed to Extract normally expelled heat from a Flue Gas Stream or a Hot Air Stream and to utilise the recovered heat for pre-heating the boiler feed water, heating ...

Manufactured by:Windsor Engineering based inPorirua, NEW ZEALAND

Utilising waste gas in process heating or power generation (gas engine) is a preferred method of disposal, but sometimes it is impractical due to distance from a suitable site. Flaring gas is the best alternative in this situation. A temporary flare may also be required for co-generation standby systems and during landfill ...

Manufactured by:Clarke Energy based inLiverpool, UNITED KINGDOM

Clarke Energy recognised the requirements for a ‘power module’ based around the GE Jenbacher Type-6 engine. The power module scope which comprises of engine, enclosure, silencer cooling system and other key ancillary components has been optimised for the requirements of the Australian coal gas and remote power ...

Manufactured by:Clarke Energy based inLiverpool, UNITED KINGDOM

Furnace gas is a gas which is produced in different types of furnace during the production of metals. High levels of power requirement and rising energy costs present a major challenge to the metallurgical industry. Some furnace gases created as a ‘free’ by-product during production processes serve as an attractive fuel for power generation. In addition to the economic benefit, using ...

Manufactured by:Clarke Energy based inLiverpool, UNITED KINGDOM

Combined heat and power (CHP) or cogeneration has significant potential in the brewery industry. Electricity and heat recovered from a gas engine can be deployed at high efficiency for useful onsite use. This gives the ability to reduce operational costs and reduce carbon emissions. Converting the heat into cooling via absorption chillers is called combined cooling heat and power (CCHP) or ...

Manufactured by:Munters based inAmesbury, MASSACHUSETTS (USA)

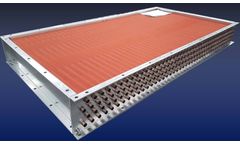

The VariMax™ OTH (Once-Through Heater) is a high efficiency, industrial, indirect-fired gas heater used to heat process air streams without contaminating the air with the products of combustion. The OTH is well-suited for recirculating ovens, dryers, makeup-air applications in cold environments, and industrial processes with moderate ...

Manufactured by:Clarke Energy based inLiverpool, UNITED KINGDOM

High levels of power requirement and rising energy costs represent a major challenge for the steel industry. Gases created as a ‘free’ by-product during steel production processes serve as an attractive energy source option for efficient power generation. In addition to the economic benefit, using these gases as engine fuel reduced industrial CO2 emissions and saves natural energy ...

Manufactured by:Clarke Energy based inLiverpool, UNITED KINGDOM

The spent byproducts of distilleries have historically been treated as waste. However, the liquid and solid wastes of the distillation industry have greater potential and can be sent to anaerobic digesters and converted into biogas. This biogas in turn can be turned into renewable electricity at high efficiency via GE Jenbacher gas ...