- Home

- Companies

- Solex Thermal Science

- Products

- Solex - Moving Bed Heat Exchangers

Solex - Moving Bed Heat Exchangers

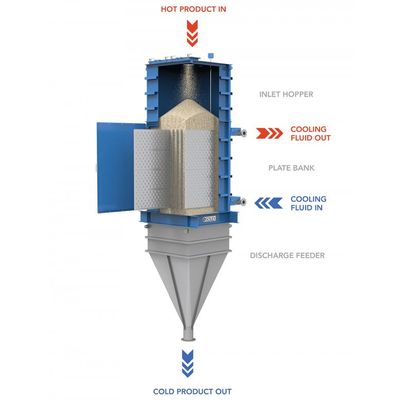

Solex's moving bed heat exchangers thermally treat bulk solids to uniform temperatures while using up to 90% less energy and producing virtually no emissions. Waste heat from elsewhere in the facility can be captured and reused, improving efficiency and generating even greater cost savings. Additionally, a vertically oriented modular design with no moving parts and a significantly smaller installation footprint than traditional methods, operators can minimize installation costs, quickly increase capacity, eliminate bottlenecks while reducing maintenance costs at the same time.Controlled Product Flow

Free-flowing bulk solids pass slowly downward between a series of vertical hollow heat exchanger plates.

Indirect Plate Heating

Steam, hot water, thermal oil or air flow through the plates to heat bulk solids material by conduction.

Mass Flow

The mass flow discharge feeder creates uniform product velocity and regulates product flow rate.

Vertical Model

Bulk solids pass through the vertical heater by gravity, using no moving parts.

Use up to 90% less energy

Indirect heating by conduction uses drastically less energy than other conventional direct heating equipment, such as fluid bed heaters or rotary heating equipment.

Recover and reuse waste energy

Indirect plate heating technology makes it possible to capture and use low-grade heat from elsewhere in your facility for heating bulk solids – whether through hot water, steam, thermal oil or air. The more recovered energy you have available, the greater the potential savings.

Prevent abrasion or degradation

The slow and controlled movement of the bulk solids material prevents product abrasion and degradation so that there is no change in particle characteristics or quality.

Receive precise & uniform final temperatures

As it is heated, your product flows with uniform velocity through the heat exchanger with a longer residence time (usually five to 10 minutes) enabling even temperature distribution and stable, uniform final temperatures.

Significantly reduce emissions, dust, fines or odors

Because no air is used during the indirect heating process, emissions, fines, dust and odors are virtually eliminated.

Eliminate costly air-handling equipment

Because air used does not contact the product directly, there is no need for air handling equipment such as large diameter air ducting, motors, fans, scrubbers, heaters and emissions controls.

Reduce your installation footprint

The heat exchanger’s modular design and vertical orientation make it an ideal choice for debottlenecking or revamping. You can quickly and easily increase capacity without sacrificing additional floor space.

Cut maintenance costs

Our heat exchangers use no moving parts, drastically reducing the maintenance required over time. Plates can be removed and replaced individually with easy access via a full-height access door.

Product temperatures:

- Up to 100°C (water)

- Up to 300°C (thermal oil, steam & pressurized water)

- Up to 700°C (Indirect air)

Capacity:

- 100 kg/hr to 100,000 kg/hr

- Biosolids — Cooling

- Catalysts — Cooling

- Cement — Cooling

- Chemicals — Heating/Cooling

- Fertilizers - Cooling

- Food Products - Heating/Cooling/Drying

- Foundry Sand - Heating/Cooling

- Minerals — Heating

- Metals — Heating

- Oilseeds - Heating/Cooling

- Polymers - Heating/Cooling

- Potash - Cooling

- Proppants - Heating/Cooling

- Sugars - Cooling

- See all