Solex - Moving Bed Heat Exchangers for Cooling Bulk Solids

Our moving bed heat exchanger technology is capable of cooling bulk solids from up to 2,000°C indirectly by conduction, consuming up to 90% less energy. It is engineered to handle substantial thermal stresses without cracking or damage, while offering guaranteed thermal performance for a superior end product.Waste heat can be recovered and used elsewhere in the facility. No air is ever in contact with the product, virtually eliminating emissions, fines, bacterial and odor contamination.

A vertically oriented modular design uses little floor space and is easily expandable should capacity requirements increase.

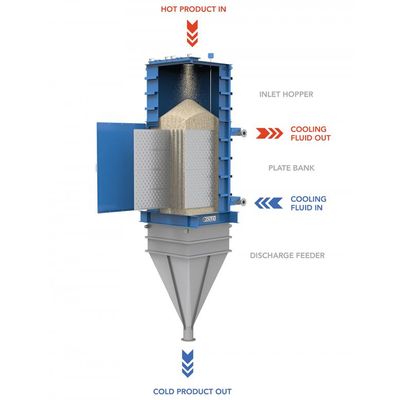

Controlled product flow

Free-flowing bulk solids pass slowly downward between a series of vertical hollow heat exchanger plates.

Indirect plate cooling

Water or gas pass through the plates to cool bulk solids material indirectly by conduction.

Mass flow

The mass flow discharge feeder creates uniform product velocity and regulates product flow rate.

Vertical model

Bulk solids pass through the vertical cooler by gravity, using no moving parts.

Save up to 90% more energy

Solex heat exchangers cool bulk solids using indirect heat transfer by conduction to substantially reduce energy requirements.

- Our bulk solids cooling technology uses indirect heat transfer, keeping air and fluid completely separate from the product being cooled. Our heat exchanger designs can use a variety of different heat transfer fluids including water, steam, thermal oil, air, nitrogen or other fluids.

- The bulk solid material moves slowly through the heat exchanger avoiding the need to energetically mix the bed of material.This drastically mitigates the risk of attrition and dust while eliminating the need for large horsepower electric drives, big motors and other energy-consuming equipment.

With liquid cooling

Heat recovered through induction cooling can be made available as high grade heat, such as pressurized hot water or steam, for use elsewhere in your facility.

With air cooling

During the cooling process, heat from the bulk solids is transferred to the cooling air, producing clean, hot air that can then be used for other processes such as pre-heating combustion gases.

Guaranteed thermal performance

We use proprietary thermal modeling software to accurately predict the product temperature profiles of bulk solids at every point through the heat exchanger for remarkably stable and uniform final product temperatures.

Virtually zero emissions; no contamination

Since the air used for cooling the bulk solids never comes into direct contact with the product, the risks of bacterial or odor contamination are virtually eliminated, as are emissions, dust and fines.

Prevent abrasion or degradation

The slow and controlled movement of the bulk solids material prevents product abrasion and degradation so that there is no change in particle characteristics or quality.

Reduce installation footprint

With its compact and modular design, our bulk solids cooling technology takes up very little floor space when compared with other cooling equipment and can be easily installed in new or existing facilities.

You can quickly and easily as capacity as needed.

Extend time between cleanings

Our bulks solids cooling systems use a counter-flow design and proprietary air injection system to secure the temperature profile of your materials and prevent condensation from forming inside the unit.

The vertical orientation of the plates (as opposed to other solutions with U-profile plating) drastically reduces the risk of caking.

Remove & replace individual plates

Every plate is connected individually with flexible hoses, enabling you to remove single plates for repair, replacement and cleaning. Other plates can be used as usual, reducing operational downtime.

The individual plate arrangement also allows for thermal expansion and reduces the risk of cracking compared to older solutions with plates welded to manifolds.

Product temperatures:

- Up to 2,000°C (water & indirect air/gases)

- 2,000°C (indirect air)

Capacity:

- 100 kg/hr to 100,000 kg/hr