Fraunhofer Institute for Ceramic Technologies and Systems IKTS

- Home

- Companies

- Fraunhofer Institute for Ceramic ...

- Products

- Silicon Nitride Materials

Silicon Nitride Materials

Application-oriented material development and modification of silicon nitride and composite materials; Design of microstructure and phase composition. Evaluation of sintering behavior and property potential of Si3N4 powders. Consulting on material selection. Development and testing of prototypes for applications subjected to mechanical, chemical and thermal stress.

Most popular related searches

silicon nitride

gas turbine engine

gas turbine engineering

power engineering

gas turbine

gas engine

power turbine

- Material selection and development for high-temperature applications up to 1500°C in different atmospheres and under different load conditions

- Applications in power engineering (hot gas turbine), engine building (ceramic glow plug) or as tool material (thixoforming)

- High-temperature materials with resistance to oxidation and corrosion

- Oxide and non-oxide fiber composite materials based on commercial ceramic fibers

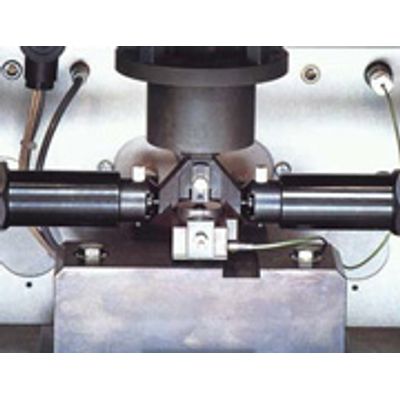

- Manufacturing of fiber composite materials by defined deposition of fiber rowings on rotationally symmetric mandrels of different geometry (winding technology)

- Adjustment of defined interactions between fibers (coating) and matrix material

- Processing of air-sensitive powders up to the nanometer range

- Closed process chain in inert gas box system (N2, ≤ 1 ppm H2O)

- Stabilization of suspensions, defined crystallization of amorphous powders

- Ddjustment of optimal surface properties, hardness as well as wear resistance

- Application in highly stressed ball bearings (mixed lubrication) as well as wear and cutting materials

- Development of spherical catalyst and sorbent materials (hollow spheres, core-shell structure)

- Optimization of properties in terms of activity/capacity and mechanical parameters

- Comprehensive characterization