Refine by

Heat Exchanger Articles & Analysis: Older

252 articles found

For example, the thermal conductivity of C11000 copper alloy is as high as 401 W/(m·K), which makes it excellent in applications such as radiators and heat exchangers that require efficient heat conduction. In addition, other data also show that the thermal conductivity of high-purity copper is usually between 393 W/m°C and 401 ...

Cooling water circuits and solar systems are often filled with water-glycol mixtures for frost protection reasons. Propylene glycol added to the water mainly serves as frost protection. The propylene glycol also provides a certain degree of corrosion protection. Due to the addition of propylene glycol, the viscosity of the circulation fluid used increases slightly and the air separation capacity ...

The heat input is a driving factor for the breakdown of complex organic molecules into simpler compounds. ...

Heat exchangers are commonly used for a wide range of purposes in the anaerobic and biogas sector, from digester heating and pasteurisation to evaporation, biogas dehumidification and exhaust gas heat recovery. ...

As we continue to innovate and adopt cleaner energy technology, renewable energy technologies are increasingly vital in our quest for sustainable and efficient energy solutions. Among these technologies, coil heat exchangers play a crucial role in enhancing the performance and efficiency of systems like geothermal heat pumps (GHPs) and solar ...

As we continue to innovate and adopt cleaner energy technology, renewable energy technologies are increasingly vital in our quest for sustainable and efficient energy solutions. Among these technologies, coil heat exchangers play a crucial role in enhancing the performance and efficiency of systems like geothermal heat pumps (GHPs) and solar ...

Regenerative Thermal Oxidizer (RTO) uses the ceramic regenerators to store the heat generated by the decomposition of VOCs, and uses the thermal energy stored in the ceramic regenerator to pre-heat and decompose the untreated VOCs, thereby achieving high thermal efficiency. The oxidation temperature is generally between 800 ° C and 850 ° C, up to 1100 ° C. Regenerative Thermal ...

Regenerative Thermal Oxidizer (RTO) uses the ceramic regenerators to store the heat generated by the decomposition of VOCs, and uses the thermal energy stored in the ceramic regenerator to pre-heat and decompose the untreated VOCs, thereby achieving high thermal efficiency. The oxidation temperature is generally between 800 ° C and 850 ° C, up to 1100 ° C. Regenerative Thermal ...

Recently, varelen design and developed mine flameproof dry transformer with active heating pipe, the company's full wave mine flameproof dry transformer products were upgraded again, creating a new era of flameproof heat dissipation. ...

High-Temperature Design Transformer are built to handle high temperatures according to IEC 60076 standards. They utilize water to fluid heat exchangers and high-temperature insulation materials. By using ester as an insulation fluid, these transformers can operate at higher temperatures than those using mineral oils. ...

Refractory Lining: Check the condition of the refractory lining inside the reactor. Cracks or erosion can lead to heat loss and structural damage. Seals and Gaskets: Examine all seals and gaskets for wear. ...

District heating—the generation of heat in a central location and distribution of it to local residences, businesses, and industry at greater economies of scale than individual heating systems—plays an important role in helping the transition to clean energy in the fight against climate change. The challenge, however, is that district heating, used to provide hot water and heat within ...

Advanced electrode boilers are being installed to replace outdated, inefficient fuel-burning equipment in district heating applications as part of broader effort to meet ambitious International Energy Agency decolonization ...

MAIN HEAT EXCHANGER TYPES Most heat transfer applications will require the use of corrugated tube heat exchangers. ...

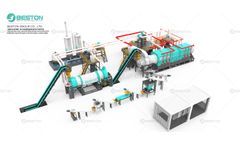

This process involves subjecting plastic materials to intense heat in the absence of oxygen, leading to their decomposition into useful byproducts such as pyrolysis oil, syngas, and char. ...

Therefore, materials with high melting points and excellent thermal stability, such as refractory metals like tungsten and molybdenum, or heat-resistant alloys like Inconel and Hastelloy, are preferred for constructing the reactor components. 2. ...

HRS is well known as a leading supplier of heat exchange, but our clients are increasingly looking for turnkey solutions for their thermal processing challenges. ...

Econotherm GW 1200 finned to finned pipe heat exchanger. 1.2MW process water heater (Genset). Remote location: chosen for high reliability, no single point of failure, low fouling,easy cleaning and low maintenance, small footprint and weight ...

However, some outdated methods release heat, smoke, dust, and fumes that can harm the environment on a large scale. That's why the most impressive machines have features that prevent heat exchange, collect fumes and dust, and ensure no harm is done to the environment. ...

Wood vinegars have a number of uses from the agricultural industry and function like a soil tonic and also natural pest repellent.2.Handling the SmokeThe most significant downside to the procedure of transforming wood along with other biological byproducts into charcoal, is definitely the great deal of smoke and also heat produced in the process. It will likely be critical that ...