Pyrolysis Process Articles & Analysis

319 articles found

What Is Pyrolysis Technology? Pyrolysis is a high-temperature, oxygen-free process that breaks down organic materials, such as plastics, biomass, and waste tires, into useful by-products like oil, gas, and char. ...

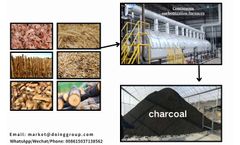

A charcoal maker machine converts biomass materials into high-quality charcoal through a high-temperature carbonization process. This process not only preserves the energy value of the raw materials but also significantly reduces the environmental pollution caused by direct incineration. ...

By incorporating specialized catalysts into the pyrolysis process, industrial operators can significantly improve oil yield, enhance product quality, and optimize energy efficiency. ...

What is Pyrolysis and Why Is It a Good Business Idea? Pyrolysis is a thermochemical process that breaks down materials at high temperatures in the absence of oxygen. This process results in valuable by-products such as oil (or pyrolysis oil), gas, and char, all of which have various industrial applications. ...

However, the quality of the carbon black produced during tire pyrolysis can vary based on several factors, and understanding these influences is essential for maximizing the value of the process. ...

Continuous biomass pyrolysis machine DOING biochar carbonization reactor is designed for continuous operation and can quickly process large amounts of biomass. ...

Coconut Shell Charcoal: A Sustainable Resource Coconut shell charcoal is created through pyrolysis, a carbonization process that converts shells into clean-burning charcoal without oxygen. ...

A palm shell charcoal machine diverts this waste stream into a controlled pyrolysis process, producing biochar instead of smoke and ash. This not only mitigates the environmental burden of waste disposal but also enables resource recovery. ...

The continuous pyrolysis equipment for plastic, tire, and oil sludge cracking has seen significant advancements in technology that offer improved efficiency, cost savings, and environmental benefits. ...

The equipment is equipped with an advanced automatic control system, which can realize accurate monitoring and regulation of the entire carbonization process. From the feeding of raw materials, the control of pyrolysis temperature to the collection of products, each link can be precisely operated through the intelligent system, which greatly improves the ...

Restoration of Soil Quality One of the primary ecological benefits of oil sludge pyrolysis is its potential to restore contaminated soils. The bio-oil produced during the pyrolysis process contains valuable organic compounds that can be used to treat degraded or polluted soils. ...

A pyrolysis reactor is a piece of equipment used in the pyrolysis process, which involves heating organic materials in the absence of oxygen to break them down into smaller, more useful components. ...

This heat causes the shells to decompose, releasing volatile gases and producing solid biochar.The by-products of the pyrolysis process, including gas and liquid oil, are captured and can be used to generate energy for the system or sold for other purposes. ...

To significantly reduce the amount of plastic waste entering the oceans, more advanced technologies need to be developed and implemented on a large scale. This is where pyrolysis technology steps in. How Pyrolysis Technology Works Pyrolysis is a thermochemical process that decomposes organic materials in the absence of oxygen, ...

Catalytic pyrolysis is a modified version of the traditional pyrolysis process. While traditional pyrolysis relies solely on heat to break down organic materials, catalytic pyrolysis introduces a catalyst into the reaction system. The catalyst acts as a facilitator, lowering the activation energy required for ...

Maximizing Pyrolysis Efficiency The pyrolysis process, wherein the raw materials are subjected to high heat in the absence of oxygen, is where the magic of charcoal production happens. ...

Biochar pyrolysis is a thermochemical process that involves heating biomass - materials such as wood, agricultural waste, or dedicated energy crops - in an oxygen - limited environment. ...

Diversified Revenue Streams One of the most compelling reasons to invest in a biochar machine is the opportunity to create multiple revenue streams. The core product of the pyrolysis process—biochar—has a range of applications across various industries, including agriculture, environmental management, and energy production. ...

However, it's important to ensure the equipment's capacity aligns with the expected demand, as purchasing oversized equipment without sufficient feedstock can result in inefficient operations and increased operating costs. 2. Type of Biochar Production Process The method used to produce biochar—whether through pyrolysis, gasification, or another ...

In fact, pyrolysis machines are designed to capture and utilize the gases produced during the process, reducing emissions and enhancing energy recovery. ...