Pyrolysis Process Articles & Analysis: Older

296 articles found

Through the integration of a charcoal making machine, this process offers a sustainable alternative to traditional practices, emphasizing resource efficiency and ecological preservation. ...

Pyrolysis is a thermal decomposition process that breaks down organic materials, such as plastic, rubber, and biomass, in the absence of oxygen. ...

To recycle plastic to fuel oil using a pyrolysis vessel, follow these steps: 1. Preparation of Plastic Material: Collect and sort the plastic waste, ensuring it is free from contaminants that may interfere with the pyrolysis process. ...

The feedstock must be processed to a consistent size for efficient pyrolysis. Typically, the material is shredded or ground to ensure uniformity. ...

The thermal efficiency of a pyrolysis reactor is a critical factor in determining the overall performance, energy consumption, and economic feasibility of the pyrolysis process. Pyrolysis, a thermochemical decomposition process, is used to convert organic materials such as plastics, rubber, and biomass into ...

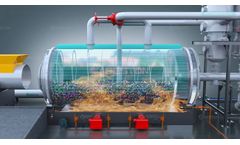

Setting up a continuous pyrolysis machine project involves a range of equipment and systems that work together to efficiently process waste materials (such as tires, plastics, rubber, medical waste, construction waste, e-waste, etc.) into useful by-products like fuel oil, carbon black, and syn-gas. ...

Overview of Plastic Fuel Oil Plastic fuel oil, also known as pyrolysis oil, is produced through the thermal decomposition of plastics in an oxygen-free environment. During pyrolysis, plastic waste is broken down into simpler compounds, resulting in a mixture of gases, liquid fuel, and solid residue. ...

Unlike batch or semi-continuous pyrolysis plants, where processing takes place in phases, continuous pyrolysis operates in a steady, uninterrupted cycle. ...

The biomass fraction of pyrolysis refers to the portion of biomass material that undergoes thermal decomposition in the pyrolysis process to produce valuable products such as biochar, bio-oil, and syngas. ...

Any failure in sealing leads to oxygen infiltration, disrupting the pyrolysis process. This not only affects the quality of the end products but also poses serious safety risks. ...

Carbonization process: the key to unlocking the potential of husk In the deep processing of rice husk, carbonization plays a core role. Carbonization is a high-temperature pyrolysis process, usually carried out under oxygen-deficient or oxygen-limited conditions, in which the organic matter in the rice husk is decomposed and ...

Mini pyrolysis plant cost differs, depending on the technology and features. ...

Contaminants are removed to improve the efficiency of the pyrolysis process. Heating: The prepared plastic waste is subjected to high temperatures, usually between 300°C and 900°C, in a pyrolysis reactor. ...

Continuous pyrolysis is a complex process that requires specialized equipment. The journey from concept to operational equipment involves several stages: Design and Engineering: This phase includes detailed equipment design, material selection, process simulation, and safety considerations. ...

In January 2014 BTG Bioliquids / Empyro BV started construction of its pyrolysis oil production facility in Hengelo, the Netherlands. The Empyro plant converts 5 tons per hour of wood residues into pyrolysis oil, process steam and electricity. ...

Pyrolysis is a transformative technology that can effectively process a wide range of waste materials, converting them into valuable products like fuel oil, carbon black, and gas. This article outlines the types of raw materials suitable for pyrolysis and describes the general process flow of a waste pyrolysis ...

Beston Group has developed a cutting-edge catalytic pyrolysis technology that significantly enhances the efficiency and environmental friendliness of the process. ...

Proper maintenance of a pyrolysis reactor is critical to ensure its efficient operation, longevity, and safety. ...

Employ cutting-edge technologies in their machines to optimize the pyrolysis process. Develop proprietary technologies that offer competitive advantages. ...

Understanding Biomass Pyrolysis Biomass pyrolysis is a thermochemical decomposition process that occurs in the absence of oxygen. ...