Refine by

Pyrolysis Process Articles & Analysis

110 news found

Pyrolysis is a thermal degradation process that breaks down complex polymer chains in the absence of oxygen. ...

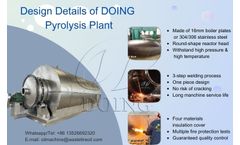

The cost of pyrolysis reactors is influenced by a range of factors, including reactor type, processing capacity, material quality, safety systems, and market factors. ...

PVC (Polyvinyl Chloride) is rarely used in pyrolysis processes—whether for waste-to-energy, fuel production, or chemical recycling—due to severe environmental hazards, equipment damage risks, and poor economic viability associated with its chlorine-rich composition. ...

Pyrolysis oil, also known as bio-oil, is a product obtained from the pyrolysis process, which involves the thermal decomposition of organic materials such as waste plastics, tires or oil sludge in the absence of oxygen. ...

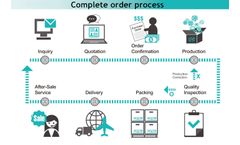

As a pyrolysis machine manufacturer, DOING Company is dedicated to delivering a smooth and efficient pyrolysis machine delivery process for our clients. ...

It not only curbs the pollution arising from waste itself but also eliminates secondary pollution throughout the recycling process. Pyrolysis equipment plant is an eco - friendly recycling approach that transforms various types of waste into fuel energy. ...

Pyrolysis is a highly efficient method for recycling rubber products, especially those that are difficult to process using conventional mechanical recycling techniques. ...

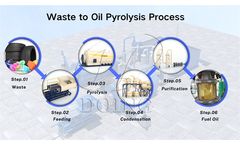

Our pyrolysis technology not only helps in managing waste but also produces valuable oil products that can be utilized in various industries.Understanding the Pyrolysis Process Pyrolysis is a thermal decomposition process that occurs in the absence of oxygen. ...

Henan DOING’s pyrolysis machines are designed to handle various types of solid and hazardous waste, including waste rubber tires, scrap plastic, oil sludge, coal tar, medical waste, and more. ② Energy Recycling The pyrolysis process transforms waste materials into valuable products such as fuel oil, carbon black, and syngas. ...

The cost of a plastic to fuel pyrolysis equipment largely depends on its model, processing capacity, the configuration, etc. ...

Pyrolysis is an effective and sustainable method for converting waste materials into valuable products. ...

Through an advanced pyrolysis process, used tyres will be converted into tyre-derived oil, which will then be refined into Sustainable Aviation Fuel and road fuels. ...

What Types of Waste Can the Machine Process? Understanding the range of organic solid hazardous waste materials a pyrolysis machine can handle is the first step in determining its suitability for your operations. ...

Mini - Scale Pyrolysis System With a daily processing capacity of merely 10 kilograms, the mini - scale pyrolysis system is an ideal choice for conducting tests or demonstrations. ...

Pyrolysis and cracking are related processes, but they are not exactly the same. ...

In contrast, TPCB is derived from end-of-life tires through pyrolysis—a process that breaks down rubber at high temperatures without oxygen, yielding oil, gas, steel, and carbon black. ...

Youngstown council voted to extend the pyrolysis moratorium first passed last year. The vote resulted in applause from audience members, as the city does what it can to stop the company’s plans. In a stunning statement Youngstown Councilwoman Anita Davis stated; “There’s no other country that has a process like this. It’s so brand new. ...

They are all available from China top pyrolysis plant manufacturer Henan Doing Company. DOING Brand Batch-type pyrolysis plants operate in a discontinuous manner, where the reactor is loaded with feedstock, sealed, and then heated to achieve pyrolysis. ...

Here's how DOING pyrolysis machines can be tailored to client needs: 1. Capacity: DOING offers pyrolysis machines in a range of capacities, from small-scale units suitable for pilot projects or localized operations to large-scale plants for industrial-level processing. Clients can specify their desired processing capacity, and ...

This aligns with sustainability goals and reduces the industry’s ecological footprint. Overall, incorporating pyrolysis oil into the metal smelting process can enhance sustainability, reduce costs, and support environmental stewardship within the industry. Then how do we produce pyrolysis oil? Production Process of ...