Pyrolysis Reactors Articles & Analysis

44 news found

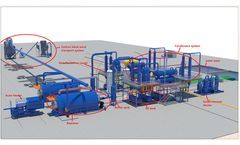

A continuous pyrolysis plant requires a coordinated system of equipment to achieve uninterrupted feeding, pyrolysis, product separation, and environmental protection. ...

Pyrolysis equipment plant stands as an environmentally friendly recycling solution for waste. ...

Pyrolysis oil: A liquid fuel blend that can be refined into diesel, gasoline, or industrial solvents. ...

Tyros, founded in May 2024, is investing in an electric pyrolysis reactor with the support of the Flemish government (1 million euros in strategic ecology support). This reactor will convert 9,125 tons of rubber granulate annually into valuable primary components such as recovered Carbon Black, pyrolysis oil and syngas. ...

Yes, plastic bags can be pyrolyzed. Pyrolysis is a thermal decomposition process that breaks down organic materials (like plastics) in the absence of oxygen, producing valuable byproducts such as pyrolysis oil, char (carbon residue), and gaseous hydrocarbons. ...

Feeding the Materials The prepared tire and plastic waste is then fed into the pyrolysis reactor. Depending on the design, this can be done manually or through an automated conveyor system. 3. Heating and Pyrolysis Reaction Once the materials are loaded, the reactor is heated to a temperature between 200°C and 350°C . ...

Pyrolysis Waste to Energy Technology is a process that converts waste materials such as municipal solid waste, agricultural waste, or industrial waste, are heated to high temperatures in a sealed pyrolysis reactor. Under these conditions, the complex organic compounds in the waste break down into simpler substances, including gases, liquids, and ...

The amount of heat required to start a pyrolysis reaction can vary depending on the type of feedstock and the specific conditions of the process. Generally, the temperature range for initiating pyrolysis is between 400°C and 600°C . For example, Plastic Pyrolysis: Typically requires temperatures in the range of 400°C to 500°C. ...

Shipping pyrolysis plant to customers typically involves several key steps and considerations: 1. **Packaging and Loading**: Pyrolysis plant components include pyrolysis reactors, condensers, oil tanks, and other equipment and require careful packaging to ensure they are fully protected during transportation. ...

Then how do we produce pyrolysis oil? Production Process of Pyrolysis Oil: A. Feedstock Preparation: Various organic materials can serve as feedstock for pyrolysis oil production, including oil sludge, waste plastics, tires, coal tar, and more. These materials are collected, sorted, and prepared for the pyrolysis process. B. ...

The continuous pyrolysis machine typically consists of several key components: 1. Feeding System: This system is responsible for automatically feeding the waste materials into the pyrolysis machine reactor. It usually includes an automatic feeding machine like screw feeders to ensure a steady supply of waste material. 2. ...

High temperature distillation The tire pyrolysis oil is transported to the distillation reactor by oil pump, and the reactor is heated by heat conduction oil and combustion machine at the same time. ...

The following is a brief introduction about the designs, configurations and advantages of our high quality pyrolysis machine: DOING high quality pyrolysis machine usually is composed of two main parts: pyrolysis reactor and condensers system. In addition, we also have other optional devices for you to choose. Part one: ...

Businesses are increasingly recognizing the immense potential of pyrolysis technology for their operations. One particularly intriguing advancement is the fully continuous pyrolysis plant reactor design. ...

This controlled thermal decomposition breaks down the tires into valuable products, including pyrolysis oil, carbon black, and gas. The process operates at elevated temperatures, typically between 300°C to 800°C.Key Factors Influencing Pyrolysis EfficiencySeveral factors influence the efficiency of the pyrolysis process, including temperature, ...

The Charcoal Making Process At the heart of charcoal making process lies a two-fold process: pyrolysis and carbonization. In the pyrolysis stage, raw biomass undergoes heating and decomposition. ...

Understanding Pyrolysis Technology Pyrolysis Process Explained: At the heart of this energy revolution lies the pyrolysis process—a thermochemical decomposition of organic materials in the absence of oxygen. ...

Put the waste tires into the reactor. 2. Heat the reactor by using fuel materials, such as coal, charcoal, fuel gas, wood etc. ...

Some good pyrolysis plant options are out there if you know what you're seeking. Listed here is a guide that will assist you out with this.Always buy a pyrolysis reactor design that is recognized for doing great work for some time. ...

Purchasing a brandname-new pyrolysis reactor might be a substantial investment. Should it be sizable, able to processing 1000s of tons of material, it could be more than six figures or higher. ...