- Home

- Equipment

- netherlands

- afterburner

Refine by

Afterburner Equipment & Supplies In In Netherlands

99 equipment items found

by:IGS Anlagentechnik GmbH & Co. KG based inGelnhausen, GERMANY

By using ceramic heat storage media in the form of saddles or honeycomb bodies, higher thermal efficiencies of up to 97% and more are possible through the system's internal regenerative heat exchanger, in contrast to the conventional TNV ...

by:IGS Anlagentechnik GmbH & Co. KG based inGelnhausen, GERMANY

In the fight against climate change, exhaust air and exhaust gas cleaning systems such as RTO/RNV systems play an important role by effectively eliminating climate-damaging pollutants from the exhaust air of a wide variety of production processes. However, the oxidation chambers of many RTO/RNV systems are often heated with natural gas, which can have a negative impact on the CO2 balance. An ...

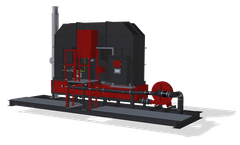

by:Greenex Eco based inHamburg, GERMANY

The combustion chamber of the crematorium furnace is designed so that the flue gases generated by combustion are held at a temperature of 850 ° C for at least 2 seconds. For complete destruction of organic matter, the crematorium furnace is equipped with an afterburner. An additional burner is installed in the afterburner, which maintains a temperature of 850 ...

Manufactured by:Wood Waste Technology Ltd based inStafford, UNITED KINGDOM

The WT5 is the smallest of the double pass heat exchange models and is a fully exempt appliance to burn chipboard, MDF, hardwood and softwood off-cuts without the need of a costly afterburner, even in city centres and built up residential areas. With a full refractory lined firebox and highly efficient double pass heat exchange with fully welded heat recovery fins the WT5 ...

Manufactured by:EBZ GmbH based inDresden, GERMANY

They are also available as fuel management package including heat exchangers / electrical gas heaters, evaporators and afterburner. We run a completely equipped reformer test rig to characterise catalysts and reformer ...

Manufactured by:Janfire based inÅmål, SWEDEN

Efficient combustion with rotating roster drum provides low operating cost. The rotating combustion chamber with ceramic afterburner chamber provides optimal combustion with the highest efficiency over the entire power span. If necessary, the power output can be easily controlled. The rotation creates turbulence for more efficient combustion, higher efficiency and lower ...

Manufactured by:Kohlbach Holding GmbH based inWolfsberg, AUSTRIA

Furnace thermal output: 5.850 - 19.800 kW. Central flow furnace with vertical afterburning zone, moving grate and water cooled compression ...

Manufactured by:Kohlbach Holding GmbH based inWolfsberg, AUSTRIA

Furnace thermal output: 5.850 - 19.800 kW. Central flow furnace with vertical afterburning zone, moving grate, water cooled compression zone and primary combustion chamber ...

Manufactured by:Wood Waste Control (Eng) Limited based inHigh Wycombe, UNITED KINGDOM

This is the smallest of the double pass heat exchange models and is fully exempt appliance to burn chipboard, MDF, hardwood and softwood offcuts without the need of a costly afterburner. Can be used in city centers and built up residential areas. With a fully refractory lined firebox and highly efficient double pass heat exchange with fully welded heat recovery fins the WWH 5 ...

Manufactured by:INTEC Engineering GmbH based inBruchsal, GERMANY

Waste heat heaters use the heat from exhaust gases from combustion processes or from hot exhaust air streams from industrial processes. The INTEC waste heat heaters are used behind solid fuel furnaces, afterburning systems, gas and diesel engines, melting furnaces and turbines in many industry sectors . ...

Manufactured by:Carbolite Gero Ltd - part of Verder Scientific based inHope, UNITED KINGDOM

The system is surrounded by a double walled, water cooled vessel. To prevent condensation of the byproducts in the gas outlet system, the tubes leading to the afterburner are heated. Debinding is normally performed at a slight overpressure, and upon request, the furnace can be configured for debinding under partial pressure. For partial pressure operation, a special oil pump is ...

Manufactured by:Major Furnace Australia Pty Ltd based inClayton, AUSTRALIA

Major has a range of incinerators to suit your needs, either solid waste, animal, pathological or biomedical, our incineration systems comply with the most stringent environmental standards. Industrial Process Odours and VOC Destruction can be achieved using our Afterburners and Thermal Oxidizers, refer to the Process section for more ...

Manufactured by:Plazarium GmbH based inBerlin, GERMANY

The industrial plasma systems can be integrated into any thermal process and are the main element of any plasma reactors for gasification, destruction and disposal of waste, afterburner and cracking chambers for gas purification from harmful impurities, plasma pyrolysis units, plasma hydrocracking units of fuel oil and heavy oil residues, plasma melting units, and other ...

Manufactured by:EBZ GmbH based inDresden, GERMANY

The test rigs can be equipped with different kinds of mechanical and electrical balance of plant components like air and gas preheaters, different kinds of humidification units, reforming units, gas coolers or heat exchangers, afterburners, power electronics, sensors and ...

Manufactured by:Birk Wärmetechnische Anlagen GmbH based inSeßlach (OT Dietersdorf), GERMANY

Regenerative (thermal) afterburning is an exhaust air purification system using oxidation and integrated heat recovery for process exhaust air preheating. Depending on the process or clean gas requirements, working temperatures of 650...900 °C are achieved in the RNV combustion chamber with corresponding residence times. Like the TNV process, regenerative ...

Manufactured by:HiTemp Tech Corporation based inRingoes, NEW JERSEY (USA)

HiTemp Process Furnace Systems are designed and manufactured for low and high BTU solids using a combination of temperature and destructive distillation to breakdown the combustibles. An afterburner system separately controls adding secondary combustion air to raise the temperature of the exhaust gases to the required operating temperature, eliminating any smoke or ...

Manufactured by:Eco Waste Solutions based inBurlington, ONTARIO (CANADA)

Two Stage Process: 1st stage (Primary Chamber) burns waste and produces inert ash and combustible gases. 2nd stage Afterburner (Secondary Chamber) combusts the off- gases to eliminate smoke and minimize ...

Manufactured by:FireLake Manufacturing based inHutchinson, MINNESOTA (USA)

Easy to use… Set timers and walk away. Thermocouple controls temperature. Available with LP, Natural Gas, or Oil burners. Afterburner is ...

Manufactured by:Inciner8 Limited based inSouthport, UNITED KINGDOM

The addition of a secondary chamber allows this model to operate without smoke, odours or harmful emissions. Fitted with a secondary chamber with afterburner functionality for the re-burn of harmful emissions through a 0.5 second retention ...

Manufactured by:Inciner8 Limited based inSouthport, UNITED KINGDOM

The i8-40G General Incinerator fits right in the middle of our standard range in terms of capacity and is a simple, effective multi-purpose incinerator with suitability for disposing of general and medical waste. This unit benefits from an advanced secondary chamber with afterburner for the re-burn of harmful emissions with a 2 second retention time. Giving you a reliable total ...