Flare Gas Recovery (Flares) Equipment

-

PremiumManufactured by Gazpack B.V.based in NETHERLANDS

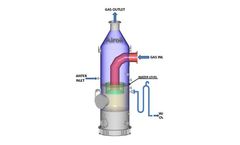

Gazpack is all aware that gas flaring is becoming a major area of concern in today’s growing market where the emphasis is hugely focused on the negative environmental impacts and how we can change these practices quickly and efficiently. Therefore Gazpack has way to shut down flares without pollution. Blended flare quencher are ...

-

based in USA

John Zink Hamworthy Combustion designs advanced flare gas recovery systems that enable facilities requiring flare systems to achieve the benefits of near-zero flaring. Flare gas recovery can result in near 100 percent reduction of normal flaring, ...

-

Manufactured by Sunpower Groupbased in CHINA

Sunpower is able to reasonably arrange discharge and recycle systems per various discharge components after making a comprehensive analysis of flare discharge gases in order to utilize different flare gas components to a maximum ...

-

Manufactured by Callidus Technologies - part of UOP, a Honeywell Companybased in USA

UOP Callidus Flare Gas Recovery (FGR) technology offers you an easy way to address growing environmental, commercial and public relations concerns regarding flaring and flare emissions. FGR technology gives your facility the ability to “recycle” flare gas. The system ...

-

Manufactured by Kobelcobased in JAPAN

are suitable for complex and dirty gas services, such as offshore vapor recovery, refinery flare gas recovery and petrochemical polymer forming gas. Kobelco supplies the most advanced oil-free screw gas compressor, with the world's largest capability - up to 142,000 m3/hr ...

-

Manufactured by Airoil Flaregas Pvt. Ltd.based in INDIA

, frequently predetermined, is reached. It acts as a diversionary unit for:- Ground flare to elevated flare systems; ground flare to ground flare systems; Elevated flare to elevated flare systems; Fuel gas recovery systems to elevated ...

-

Manufactured by Gas Compressors Ltd (GCL)based in UNITED KINGDOM

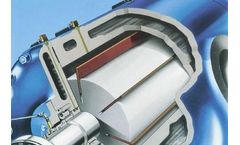

Twin screw shaped meshing rotors are mounted in a figure of eight shaped housing, which has suction and discharge ports at either end. As the rotors turn they form a space that traps gas, the space travels down the length of the housing, and because of the profile of the screws, is compressed as it goes. Due to no lubricant in the ...

-

Manufactured by K & S Equipment and Machinery Corporationbased in USA

Our team of engineers and technicians are aware of the varying needs of vacuum technology for different applications. We offer unmatched expertise in the design and manufacture of systems to meet the specific needs of your processes. The systems can be easily integrated into your operation and assist in minimizing ...

-

Manufactured by Gas Compressors Ltd (GCL)based in UNITED KINGDOM

the trapped gas to be compressed. Ports in the housing wall are positioned to let the gas in and out at the points of minimum and maximum pressure. Fully oil flooded versions are also available, with no oil loss to process. ...

-

Manufactured by Leobersdorfer Maschinenfabrik GmbHbased in AUSTRIA

This type series has a modular structure with strokes of 90, 120, 150, 180, 250 und 360 mm. One to six cylinders are arranged either vertically (in line), horizontally (opposed cylinder type) or in V-design. Ultimate pressures of up to 250 bar with non-lubricated cylinders or 700 bar with lubricated cylinders are possible. An output between 65 kW and 1,035 kW per cylinder allows an overall output ...

Need help finding the right suppliers? Try XPRT Sourcing. Let the XPRTs do the work for you